SST-36-NE

Ford 4×2 Steel body

Articulated Telescopic

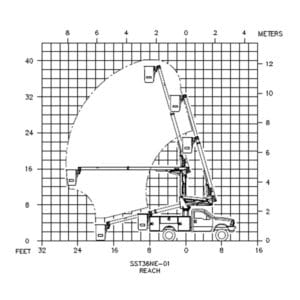

Working Height: 40.5 ft (12.19 m)

Horizontal Reach: 26.58 ft (7.92 m)

Platform Capacity: 350 lbs. (158.7 kg)

• Best in class payload due to smarter, lightweight aerial lift design

• Preferred service vehicle for leading telecommunications providers

• Ease of Maintenance: Non-lube bearings and open center system

A LIGHTWEIGHT TELECOMMUNICATIONS WORKHORSE

(Images and specs shown for reference)

______________________________________________________

INDUSTRIES SERVED

Sign, Light & Traffic, Telecommunications

TYPE

Articulated Telescopic

MODEL SERIES

SST

Product Overview

Working Height

40.5 ft (12.19 m)

Horizontal Reach

26.58 ft (7.92 m)

Platform Capacity

350 lbs. (158.7 kg)

Material Handling

No

Insulation

No

Availability

Available subject to prior sale

Sales Representative

Michael C. O’Flaherty

Retail Price

Please Contact Us

Description

Bucket Truck for Sale – VERSALIFT SST-36-NE a non-insulated, end mounted 35 ft. 6 in. (10.8 m) telescopic articulating aerial platform lift, 40 ft. 6 in. (12.3 m) working height including the following standard and optional features:

- Standard platform capacity of 350 lbs. (158.7 kg).

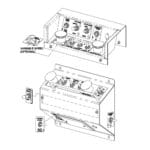

- Upper controls consist of a series of spring loaded toggle switches and a master control switch.

- Engine start/stop system with controls at platform and remote handheld lower controls.

- 370° non-continuous rotation with a mechanical stop.

- Open center hydraulic system operates at 1.5 to 2 GPM (6-8 LPM) at 2000 psi (140 kg/cmۜ)

- External hydraulic oil reservoir with 6 gal. (23 l) capacity.

- Outer boom consists of a 6 in. X 8 in. (150 mm x 200 mm) steel section

- 5 in. X 7 In. (130 mm x 180 mm) rectangular aluminum inner boom housed within the outer boom.

- End mounted walk in 24 in. x 30 in. x 42 in. (0.61 m x 0.76 m x 1.07 m) fiberglass platform.

- Manual rotator for platform.

- Master/slave hydraulic leveling with upper control to tilt for cleanout or rescue.

- Non‑lube bearings used at all pivot points.

- Multi‑link hose carrier system through booms.

- Rubberized boom cradle

- 12 volt DC backup pump providing power to all boom functions.

- Mounting hardware for chassis/cab installation.

- Handheld remote lower control with series of spring loaded toggle switches and control selector switch

- GFCI receptacle for 120 volt power at platform

- Full body harness and lanyard.

- Painted standard white urethane.

- Two operator’s manuals and two service manuals.

- ANSI A92.2 data plate.

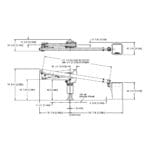

Steel Service Body 108” Long x 40” High x 94” Wide:

- 12 gauge tread plate floor with 6” structural channel frame

- 40 in. compartment height, 20 in. compartment depth, 54 in. floor width.

- Stainless steel automotive rotary type door latches.

- Chain stops on all doors

- Rubber rolled crown type fenders

- Removable composite tailboard installed at rear.

- 30” tread plate tail shelf with 7-lamp light bar installed.

- Master locking system.

- Curb side compartments as follows:-

- 1st Vertical: Two (2) adjustable shelves with adjustable dividers on 4 inch centers

- Horizontal: Open

- Rear Vertical: Two (2) adjustable shelves with adjustable dividers on 4 inch centers

- Street Side Compartments as follows:-

- 1st Vertical: Two (2) adjustable shelves with adjustable dividers on 4 inch centers

- Horizontal: One (1) removable shelf with dividers on 6 inch centers

- Rear Vertical: Five (5) fixed material hooks (1-3-1)

Cab and chassis to the following specifications:

- Ford F-450 4×2 cab and chassis with a 60” cab to axle.

- 16,000 lb. GVWR.

- 3L 2V DEVCT NA V8 gasoline engine

- TorqShift 10-speed automatic transmission.

- 88 limited slip axle.

- 225/70R19.5G BSW A/P tires.

- Air Conditioning

- XL value package includes 4.2”center-stack screen and SYNC communications system

- Power equipment package includes power windows, door locks and remote keyless entry.

- Steering wheel mounted cruise control.

- Radio: AM/FM stereo/MP3 player.

- Trailer brake controller

- Snow plow prep package.

- Rear view camera and prep kit.

- Painted Oxford White.

Installation to include the following:

- Install VERSALIFT SST-36-NE, mounting hardware, and belt drive system.

- Install rear torsion bar.

- Install and paint Dakota service body and accessories.

- Install ladder rack with hold down and locking feature.

- Install two (2) amber strobe lights in tail shelf and two (2) strobes lights in front grill

- Install Dimensions 2000 watt Pure Sine inverter with battery and box (curbside front compartment)

- Install combination pintle hitch with 2” ball, D rings and 7 prong trailer connector

- Install mud flaps, back up alarm and park brake interlock system.

- Furnish fire extinguisher, 3 piece triangle reflector kit and pair of rubber wheel chocks.

- Test ride completed unit for 1 hour.

- Test and certify per ANSI A92.2.