VST-47-MHI – Dodge 5500 4×4 – Steel body

Articulated Telescopic

Working Height: 51.83 ft (15.54 m)

Horizontal Reach: 30.75 ft (9.14 m)

Platform Capacity: 400 lbs (181.44 kg)

Jib Capacity: 1,000 lbs (454 kg)

• Best in class payload due to smarter, lightweight aerial lift design

• Unprecedented Lineman Protection at the Platform

• Ease of Maintenance: Non-lube bearings, open center system

LIGHTEST INSULATED MATERIAL HANDLER IN ITS CLASS

(Images and specs shown for reference)

______________________________________________________

INDUSTRIES SERVED

Electric Power Distribution, Electric Utilities

TYPE

Articulated Telescopic

MODEL SERIES

VST

Product Overview

Working Height

51.83 ft (15.54 m)

Horizontal Reach

30.75 ft (9.14 m)

Platform Capacity

400 lbs (181.44 kg)

Material Handling

Yes

Insulation

Yes

Availability

Available subject to prior sale

Sales Representative

Michael C. O’Flaherty

Retail Price

Please Contact Us

Description

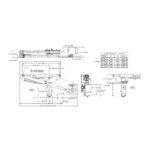

Bucket truck for Sale – VERSALIFT VST-47-MHI, insulated 47 ft. 4 in. (14.4 m) articulating, telescopic aerial platform lift, 52 ft. 4 in. (16.0 m) working height with a horizontal reach of 30 ft. 9 in. (9.4 m) and to include the following items:

- Standard platform capacity of 400 lbs

- TruGuard™ dielectric isolating system with right hand single-stick control. All control handles are isolated and tested per ANSI A92.2-2009. The high resistive dielectric system is protected from direct environmental and job related contamination. TruGuard™technology incorporates the use of full hydraulic controls with durable metal handles and linkages.

- Hydraulic platform rotator.

- Hydraulic dual arm articulating jib pole and winch package for up to 1,000 lbs. (454 kg.) capacity, including insulated jib pole

- 360o continuous rotation including slip rings

- Six GPM (22.7 lpm) open center hydraulic system with a 3000 psi (210 kg/cm²) operating pressure

- Side mounted telescopic upper boom allows low stowing of platform. Fiberglass inner boom and patented ELECTROGUARD provide insulation gap of 41 inches (1.0 m) fully retracted meeting ANSI A92.2 requirements for Category C 46KV and below.

- Chassis insulating system (fiberglass lower boom insert) providing 12 in. (0.305 m) insulation gap and including accommodations to bridge insulation gap for testing per ANSI A92.2

- ELECTROGUARD and inner boom finished with white urethane paint over a white gel coat.

- Non-lube bearings used throughout.

- One set of hydraulic tool outlets with pressure limit valve. Valve can be adjusted from 1000 to 2500 psi.

- Sub frame mounted main A-frame outriggers with pivot feet, two control valves, and a selector valve.

- Auxiliary independent narrow knock down A Frame outriggers with pivot feet

- Outrigger boom interlock system for main and auxiliary outriggers

- Integral reservoir with a 17-gallon (64.4 l) capacity and dual sight gauges.

- Side mounted closed heavy-duty one-step 24 in. X 30 in. X 42 in. (0.61m X 0.76m X 1.07m) fiberglass platform including platform liner and vinyl cover.

- Individual full pressure controls at the turret actuate all boom functions and is equipped with a selector valve to override upper controls

- 12 volt DC backup pump providing power to all boom functions

- Automatic throttle control for Dodge chassis

- Auto boom latch for mounting on inner boom. The rotary auto boom latch works off the lift hydraulic pressure to open and close.

- Standard white urethane paint

- Safety harness and lanyard

- Two operator manuals and service manuals

Cab and chassis to the following specifications:

- 2019 Dodge 5500 4×4 cab and chassis with a CA of 84”

- GVWR: 19,500 lbs payload.

- 7L I6 Cummins Turbo diesel engine

- 6-speed Aisin AS69RC HD automatic transmission

- Heavy duty front suspension group

- Tradesman Level 1 equipment group

- Electrical accessory group

- Air conditioning.

- Cold weather group including engine block heater

- 225/70Rx19.5G all traction tires.

- Uconnect 3 with 5” display

- HD vinyl 40/20/40 slit bench seat

- Parkview rear back up camera

- Transfer case skid plate shield

- Painted Bright White clearcoat.

132” long x 94” wide service body including the following:

- 30 inch tread plate platform extension

- LED lighting package installed in tail shelf.

- Access step at rear and side access.

- Two (2) chrome grab handles at side access and two (2) pool type grab handles for rear tail shelf.

- Wheel chock storage with pendulum retainers and outrigger pad holders.

- Master door locking system, excludes 1st vertical curbside

- 48” High Street side compartments as follows

- 1st Vertical: Two (2) adjustable shelves with dividers and cutout for outrigger

- 2nd Vertical: Two (2) adjustable shelves with dividers

- Horizontal: Adjustable dividers installed in compartment bottom.

- Rear Vertical: Two (2) adjustable shelves with dividers

- Hot stick shelf with rear access door.

- 40” High Curbside compartments as follows

- 1st Vertical: Two (2) adjustable shelves with dividers and cutout for outrigger

- 2nd Vertical: Gripstrut access steps to bed area with removable composite side gate.

- Horizontal: One (1) adjustable shelf with dividers

- Rear Vertical: Five (5) fixed material hooks 1-3-1

Installation to include the following:

- Install VERSALIFT VST-47-MHI, mounting hardware, PTO and pump.

- Install service body and accessories.

- Install combo pintle hitch, D rings and 7 prong trailer connector.

- Install two (2) amber strobe lights in tail shelf and two (2) strobe lights in front grill.

- Install grounding kit, park brake interlock system, back up alarm and mud flaps.

- Supply outrigger pads, wheel chocks, fire extinguisher, and 3 piece triangle reflector kit.

- Test ride completed unit for one (1) hour.

- Test and certify per ANSI A92.2