VTP-40-NE

Ford F-750 4×2 Steel Body

Cable Placer

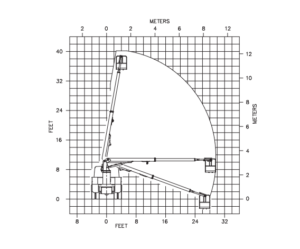

Working Height: 40 ft (12.19 m)

Horizontal Reach: 29.59 ft (8.84 m)

Platform Capacity: 500 lbs (226.8 kg)

• Full-pressure hydraulic single stick platform control, for greater featherability

• Largest platform in product category (32″ X 32″ X 43″)

Ease of Maintenance: Non-lube bearings, open center system

VERSATILE HEAVY-DUTY CABLE PLACER

(Images and specs shown for reference)

______________________________________________________

INDUSTRIES SERVED

Telecommunications

TYPE

Cable Placer

MODEL SERIES

VTP

Product Overview

Working Height

40 ft (12.19 m)

Horizontal Reach

29.59 ft (8.84 m)

Platform Capacity

500 lbs (226.8 kg)

Material Handling

No

Insulation

No

Availability

Available subject to prior sale

Sales Representative

Michael C. O’Flaherty

Retail Price

Please Contact Us

Description

Bucket Truck for Sale – VERSALIFT VTP-40-NE a non-insulated, 35 ft. (10.7 m) telescopic articulating aerial platform lift, 40 ft. (12.2 m) working height including the following standard and optional features:

- Standard platform capacity of 350 lbs. (158 kg), plus 150 lbs. (68 kg) cable down force.

- Boom tip side load capacity is 600 lbs. (270 kg) when fairlead retracted and 450 lbs. ((200 kg) when extended.

- Full pressure UNITROL single stick control with integral safety trigger and emergency stop control

- Engine start/stop system with controls at platform and lower controls.

- 370° non-continuous rotation with a hydraulic stop.

- Closed center hydraulic system operates at 12 GPM (38 LPM) at 2250 psi (175 kg/cmۜ)

- Integral hydraulic oil reservoir with 30 gallon (115 liter) capacity.

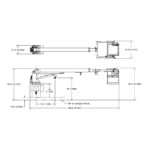

- Outer boom consists of a 10 in. x 10 in. (254 mm x 254 mm) steel section

- 8 in. x 8 in. (203 mm x 203 mm) rectangular steel inner boom is housed within the outer boom.

- 32 in. x 32 in. x 42 in. (0.81 m x 0.81 m x 1.09 m) steel platform with door and safety chain.

- Intercom with cab and platform speakers and volume control in cab

- 2000 lbs. (900 kg) rated lower boom lifting eye

- 12 volt DC backup pump providing power to all boom functions.

- 6000 lbs. (2700 kg) reel loader for reels up to 64 in. (1.7 m) wide and 84 in. (2.1 m) diameter

- Hydraulic powered cable retriever drive includes clutch to allow the reel to free wheel and hydraulic caliper disc brake to tension cable. Provides 36,000 in-lbs. (4070 N-m) drive and torque and a maximum drive speed off approx. 12 rpm. The reel drive control is included with the lower control pendant and the proportional reel brake is located in the cab.

- 2000 lbs. (900 kg) capacity strand carrier designed to carry strand reels up to 28 in. (0.71 m) wide and 32 in. (0.81 m) diameter, includes a hydraulic caliper disc brake to tension the strand providing 9600 in-lbs. torque. The proportional reel brake control is located in the cab.

- Swivel bull wheel system, mounted on boom rest

- Deck mounted four-way roller fairlead (bolted behind pedestal)

- Complete sub-frame and mounting hardware for chassis/cab installation.

- Complete boom rest assembly with polyethylene cradle for outer boom.

- GFCI receptacle for 120 volt power at platform

- Remote wired lower control box with the following functions: boom up/down, extend/retract, rotate, leveling, winch, reel lift, reel drive and capstan.

- Tow line winch (worm gear type) mounted at lower boom rest structure, includes control at platform and pedestal with 70 ft. of rope installed. Bare drum capacity of 1500 lb.

- Worm gear capstan assembly to the curbside reel lift arm

- PTO and pump for mobile operations with over speed limit (2250 psi, 12 GPM at idle, closed center)

- Aluminum tool tray 6.25 in. x 12 in x 23 in (160 x 305 x 580 mm) attaches to top rail of platform.

- Aluminum small parts tray 5 in. x 5 in. x 19 in. (130 x 130 x 480 mm) attaches to platform or tool tray.

- Full body harness and lanyard.

- Painted standard white urethane.

- Two operator’s manuals and two service manuals.

- ANSI A92.2 data plate

Cab and chassis to the following specifications:

- Ford F-750 4×2 cab and chassis.

- 25,999 lb. GVWR.

- 84” cab to axle.

- 7L Power Stroke V8 (270 HP) Turbo diesel engine

- Ford TorqShift HD 6-Speed automatic transmission

- Single channel – straight “C” 14.18 SM, 120,000 PSI frame

- 50 limited slip axle.

- Hydraulic brake system – Bosch HydroMax

- 5×8.25 powder coated steel disc wheels with 11R22.5G tires.

- 30/70 Air ride driver (Integral air pump) and fixed 2-passenger bench – vinyl

- AM/FM radio.

- Painted Oxford White.

Steel Service Body 135 in. long x 47 in. high x 94 in. wide to include the following:

- 47 in. compartment height, 20 in. compartment depth, 54 in. floor width.

- Stainless steel automotive rotary type door latches, with chain stops on all doors

- Rubber rolled crown type fenders

- Wheel chock storage with pendulum retainer

- 6 in. removable composite rails x full perimeter of tailshelf (incl. rear) for material containment

Curbside compartments as follows:-

- 1st Vertical (32 in.): Nine (9) fixed material hooks 3-3-3, one fixed shelf

- Access Steps: 24 in. wide, hinged gripstrut access steps with battery storage with one (1) gas assist door opener, two (2) chrome handles and one (1) cable step

- Horizontal (57 in.): Open

- Curbside Tailshelf Box: 28 in. x 24 in. x 20 in. box with vertical hinged access door

Streetside compartments as follows:

- 1st Vertical (25 in.): Six (6) fixed material hooks 3-3-0

- 2nd Vertical (25 in.): Six (6) fixed material hooks 0-3-3, NO wall between 1st and 2nd verticals

- Horizontal (57 in.): Open

- Streetside Tailshelf Box: 28 in. x 24 in. x 20 in. box with vertical hinged access door

Installation to include the following:

- Install VERSALIFT VTP-40-NE, mounting hardware, PTO and pump.

- Install rear torsion bar.

- Install Dakota service body and accessories

- Paint body and accessories white and non-skid body floor area.

- Install amber strobe lights one each side of turret.

- Install front strobe lights in grille and rear strobe lights on rear body panel

- Install Dimensions Pure Sine inverter with battery to be tied into 120V outlets at platform.

- Install brake controller, T-60 medium duty pintle hook, D rings, 4-way and 6-way trailer connector

- Install rear mud flaps and pipe cone holder with base (located to rear of tower on body floor).

- Install manual holder in cab and five (5) gallon water cask with storage bracket on top of body compartment.

- Install fire extinguisher with storage bracket (mount inside streetside front compartment)

- Mount convex mirror (top of streetside mirror) to view basket during mobile operation.

- Furnish ten unit medical kit including supplies, pair of rubber wheel chocks and DOT triangle type road reflector kit.

- Test ride completed unit for 1 hour.

- Test and certify per ANSI A92.2.