Bucket truck safety is fundamental to every piece of equipment that we build at Versalift. In the electric utility industry, there are several serious safety considerations that must be taken to protect linemen when they are working. Among these considerations, one of the most important is dielectric isolation, which prevents injury from electric shock. TruGuard® creates dielectric isolation for all of the upper controls in an insulated unit. A major safety innovation in insulated aerial lifts, TruGuard provides an additional layer of protection to linemen working in the bucket. The TruGuard® Safety System comes standard on every new Versalift insulated aerial lift.

TRUGUARD™ SAFETY SYSTEM – EXPLAINER VIDEO

Contact | Share | Download

April is a month to celebrate linemen and the incredible impact they have on our lives, here in the United States. Linemen are essential to our American way of life because they work hard, despite weather and hazards, to keep the lights on and the power flowing, while responding to daily issues in their communities. If you happen to encounter a lineman this month, you might consider taking a moment to thank them for their hard work!

Bucket Truck Safety & Electric Utility Companies

Bucket truck safety isn’t just important to manufacturers. It is also a huge piece of the calculation that electric power providers must make. The majority of Americans get their electric power from Investor-Owned Utilities. Most linemen in the United States either work for Investor-owned Utility Companies (IOUs), Municipal Electric Utilities or Rural Electric Cooperatives. There are currently more than 115,000 professional linemen in the United States, and they face the same sets of risks every day.

Linemen & the Electric Utility Infrastructure

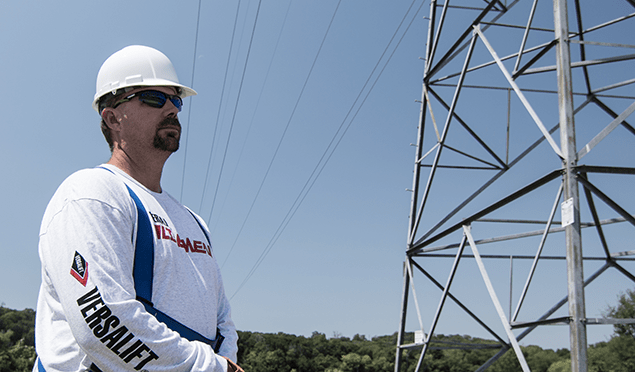

Linemen in the United States work to maintain more than 170 million wooden electric utility poles that support more than 9 million miles of electric utility distribution line. Typically, utility poles are placed approximately 300 feet apart in rural parts of the United States, and about 125 feet apart in suburban and urban parts of the country. In the United States, linemen work within the organizations that are responsible for an additional 2.7 million electric utility transmission towers, and the high voltage cables they support.

Bucket truck safety becomes most serious when working on electric power transmission infrastructure. Maintaining electric power transmission plant is where linemen are exposed to the greatest risks that they can face on the job. The two most serious hazards that linemen face are injury from electric shock and injury from falling. In the case of electric power transmission, both the current and the height of the work is very significant. It is their training, expertise and caution that makes linemen so excellent at what they do.

Linemen Are There When Disaster Strikes

When disaster strikes, linemen mobilize, entering stricken areas and re-establishing the safe flow of electric power to communities. For example, more than 67,000 linemen responded to Superstorm Sandy in October of 2012, which caused destruction and loss of life up the American east coast, from the Caribbean to Canada.

Lineman Facts You May Not Know:

-

Although the profession is called “line-man”, thousands of women work in the profession, braving the daily hazards of live line work.

-

The first lineman in the United States was named Ezra Cornell. Cornell built the Morse Telegraph Line, and then went on to found Cornell University.

-

Linemen used their bare hands to perform live line work until the introduction of ‘rubber gloving’ in 1920.

-

The average lineman carries 30 lbs of gear while they work.

Bucket truck safety is our priority at Versalift because the brave men and women who help to keep the lights on and the power running deserve every advantage they can get. This April, we are grateful to American for their dedication and hard work.