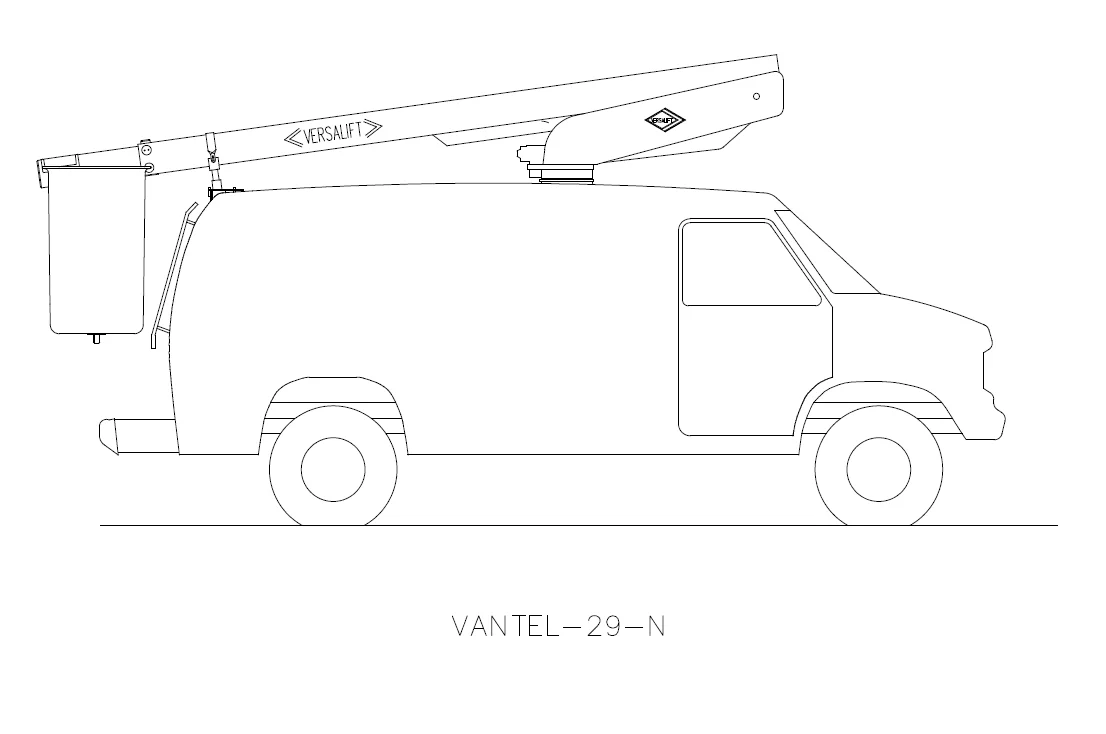

Telescopic

Telescoping bucket trucks for a variety of industries

Versalift telescopic aerial lifts are bucket trucks designed for flexibility, making them valuable service vehicles across multiple industries. With a broad range of options and configurations, fleets can equip their crews with the right tool to get the job done safely and efficiently – the first time.

Industries Served by Telescopic Bucket Trucks

Versalift telescopic bucket trucks deliver safe and reliable access across a range of industries, including:

- Telecommunications – Supporting network expansion, upgrades, and maintenance.

- Electric Utility – Providing crews with efficient access for service and repair work.

- Sign, Light & Traffic – Installing and maintaining signage, streetlights, and traffic signals.

Distribution – Ensuring dependable access for local power distribution systems.

Why Choose Our Telescopic Bucket Trucks

Whether your crews work in telecom, utilities, or sign and light installation, our telescopic bucket trucks are built to meet their needs. Explore the features that set them apart below.

Broad Range of Working Heights

Versalift telescopic bucket trucks are built for flexibility across industries and applications. With working heights from 34’ to 67’ and impressive horizontal reach, they adapt to almost any job.

At the top of the range is the Versalift LT 62, which delivers a 67’ working height. Its compact H-frame outriggers provide maximum reach while fitting into a single parking space. This creates a unique balance of height, stability, and lightweight design.

Built with Attention to Detail

Every telescopic bucket truck is crafted with precision to meet customer requirements – whether driven by industry, company standards, climate, or geography.

This attention to detail ensures that every Versalift telescopic unit upholds the same high standards of safety, quality, and reliability, regardless of configuration or customization.

Telescopic Bucket Truck Options & Configurations

Versalift has been building telescopic aerial lifts in the United States since 1965, combining proven craftsmanship with continuous innovation. Over the decades, the telescopic series has become a trusted choice for fleets that need compact design, strong reach, and long-term reliability.

Our team works with you to configure the features, options, and working envelopes that match your specific applications – from telecom service trucks to electric utility distribution and sign/light work. Each build delivers the same commitment to safety, durability, and efficiency your crews can rely on every day.

World’s First Articulated Telescopic Aerial Device – 1980

We pioneered the first articulated telescopic lift in 1980, and while the industry has changed, our approach has not. Every Versalift is built for long-term reliability, which is why it’s common to see trucks still in daily operation more than 30 years after they were built.

Versatile Aerial Lifts Tailored for Your Industry

From utilities and telecommunications to tree care, signage, and wind energy—Versalift® builds aerial lifts that match the unique needs of your industry.

With proven reliability and the lowest true cost of ownership, our equipment keeps your teams working safely and efficiently.

Forestry & Tree Care

Specialized lifts for safe tree care applications

Explore our products

Sign, Light & Traffic

Efficient access for signs, lighting, and traffic systems

Explore our products

Tele-communications

Bucket trucks for maintaining telecommunications networks

Explore our products

Municipalities

Trusted fleet solutions for local infrastructure needs

Explore our products

Safety First

Advanced safety features like TruGuard™ and SlopeMax.

Quality Assurance

Our QA247 is the foundation of every product we assemble.

Lighter Build

Heavyweight Performance – Best in class payloads and lighter chassis options.

Easy to Service

We design our products with easy maintenance in mind.

Unique Versalift Features

At Versalift, innovation and quality drive everything we do. Our bucket trucks are engineered with exclusive features that keep crews safe, reduce downtime, and extend equipment life:

- TruGuard™ – Standard on every insulated unit, this proprietary isolating system adds an extra layer of protection against phase-to-phase and phase-to-ground electrical contact.

- Non-Lub Lift Bearings – Designed to last the life of the truck with little to no maintenance required.

- Torque Striping – All critical bolts are torque-seal marked, giving operators a quick visual check for safety and efficiency.

- No Mandatory Tear-Down – Built to the highest standards, Versalift trucks deliver long-term reliability without forced downtime.

- Dual Pin Retention – Every critical pin has a redundant backup, torque-striped for added safety and peace of mind