Non-CDL Insulated Articulated/Telescopic Aerial Device

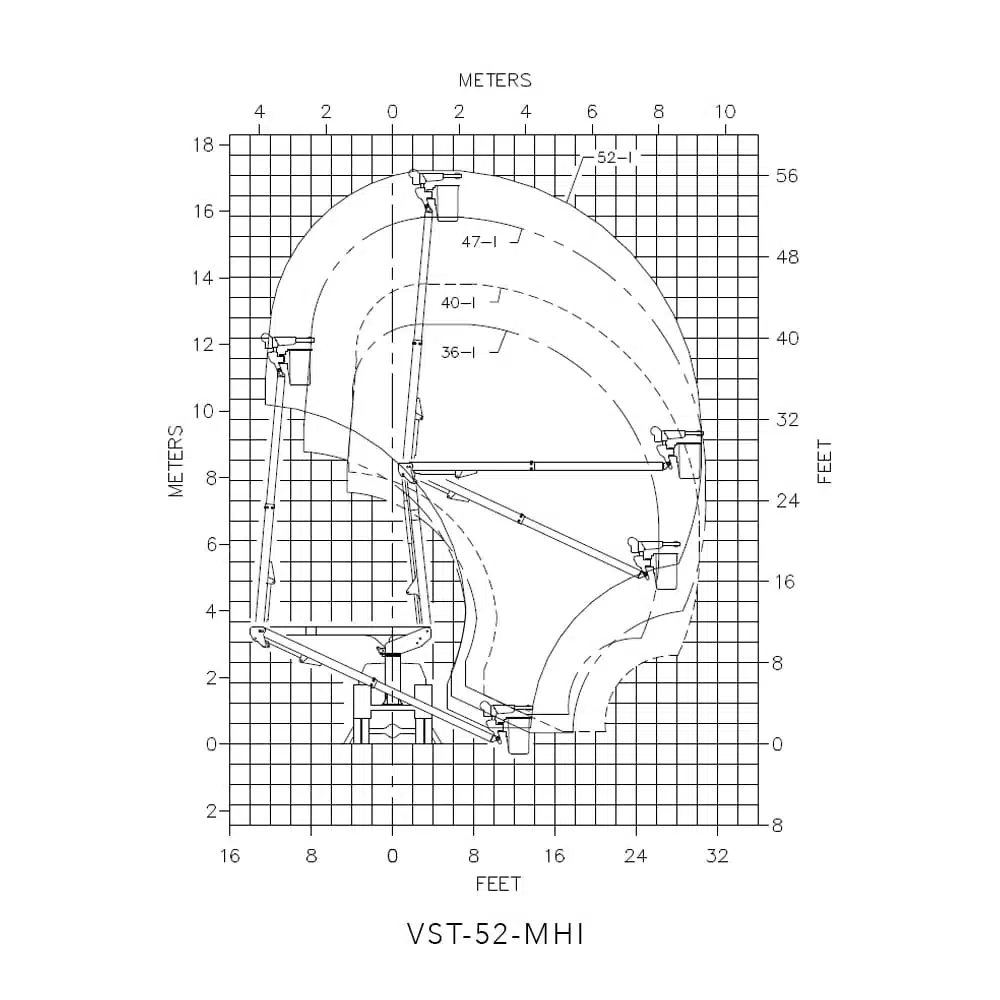

VERSALIFT VST-55-HDI, insulated 54 ft. 7 in. (16.6 m) articulating, telescopic aerial platform lift, 59 ft. 7 in. (18.2 m) working height with a horizontal reach of 33 ft. 5 in. (10.2 m) and to include the following items:

Cab and chassis to the following specifications:

Aluminum Service Body 132” Long x 48/40” High x 94” Wide to include the following:

Curb side compartments as follows: –

Street side compartments as follows: –

Installation to include the following:

Versalift US designs and manufactures high-quality aerial lifts, bucket trucks, digger derricks, and specialized access equipment for industries like electric utility, telecommunications, forestry, and lighting. Our products are built for safety, reliability, and long-term performance in the most demanding work environments.

Advanced safety features like TruGuard™ and SlopeMax.

Our QA247 is the foundation of every product we assemble.

Heavyweight Performance – Best in class payloads and lighter chassis options.

We design our products with easy maintenance in mind.

Have questions about our bucket trucks or need help finding the right solution? Fill out the form below, and a member of our team will get back to you shortly.