A digger derrick is a multipurpose, truck-mounted machine designed to drill holes, lift heavy materials, and set poles or structural supports. It’s most commonly used in utility and telecommunications work, but it also plays a key role in construction, infrastructure, and municipal projects.

What makes a digger derrick unique is its ability to perform multiple tasks with a single piece of equipment. Instead of bringing separate machines to the job site for drilling, lifting, and placing, a digger derrick combines those functions into one unit. This streamlines operations, saves time, and reduces the need for extra crew or vehicles.

Digger derricks are built for demanding field conditions. They can operate in urban environments, rural areas, and off-road locations, handling tasks like:

Whether you’re replacing a damaged pole after a storm or drilling footings for new equipment, a digger derrick delivers the power, reach, and control needed to get the job done safely and efficiently.

A digger derrick is built to perform three main tasks: drilling, lifting, and setting. Its true value lies in how efficiently it combines these functions into a single operation.

Drilling

At the heart of every digger derrick is a hydraulic auger used to drill holes in the ground. Whether the soil is sandy, clay-based, rocky, or frozen, the auger can be equipped with the right bit to match the conditions. This makes the machine ideal for:

The ability to drill on-site saves time and eliminates the need for separate boring equipmen

Lifting

Once the hole is drilled, the derrick’s boom and winch are used to lift materials into place. This includes poles, crossarms, transformers, and other heavy components. With various boom lengths and lifting capacities available, operators can position loads precisely — even at full extension or in challenging terrain.

Setting

The final step is placing the object securely into the hole. With the stability provided by hydraulic outriggers and precise boom control, digger derricks allow crews to set poles or structures quickly and safely. This is especially useful when working in remote areas where speed and accuracy matter.

By handling all three stages of the process (drill, lift, set) the machine reduces the number of machines needed on site, minimizes downtime, and helps crews work more efficiently.

A digger derrick brings together several key systems that work in sync to handle demanding field tasks. Understanding these components helps operators and decision-makers get a clearer sense of what the machine can do — and how to choose the right setup for the job.

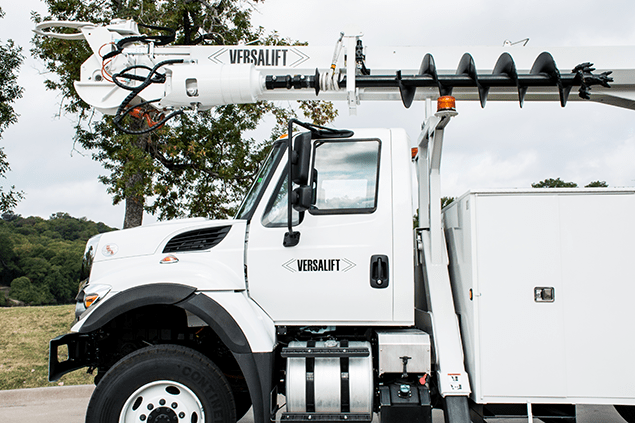

Telescopic Boom

The boom is the main lifting arm of the digger derrick and plays a central role in both lifting and setting operations. Versalift digger derricks are equipped with telescopic booms, which extend in a straight line to provide reliable vertical and horizontal reach.

Telescopic booms are ideal for pole work and other utility applications that require height, stability, and controlled positioning. They offer excellent sheave height and load handling across a wide range of working radii, making it possible to place heavy components accurately without the need for repositioning the vehicle.

Auger Drive and Torque System

Mounted near the boom, the auger system is used to drill holes in various soil types. It’s powered hydraulically and rated by its torque capacity, which determines how effectively it can penetrate different ground conditions — from soft earth to compacted or rocky soil. Auger bits can be swapped out depending on the job requirements.

Winch and Sheave Assembly

The winch and sheave system enables the controlled lifting and lowering of poles, anchors, and other materials. The sheave, located at the boom tip, allows the winch line to run smoothly and supports precise load placement. Together, this system is essential for safe and accurate material handling.

Outriggers (Stabilizers)

Outriggers are hydraulically operated supports that extend from the sides of the truck to provide a stable working base. They are critical for maintaining balance and safety, particularly when lifting heavy loads or working with the boom fully extended. Proper outrigger deployment is a key part of every setup.

Explore our full range of digger derricks here.

Digger derricks are used in a wide range of industries that require precision drilling, lifting, and setting of poles or structural components. Their versatility makes them an essential tool in both day-to-day operations and large-scale infrastructure projects.

Here are some of the most common industries and how they use digger derricks:

Electric Utilities

Electric utility companies rely heavily on digger derricks for installing and replacing power poles, transformers, and other infrastructure. Whether it’s routine maintenance or emergency storm response, digger derricks help crews work quickly and safely in the field.

Telecommunications

Digger derricks are ideal for setting telephone poles and telecom structures, especially in rural or suburban areas. Their ability to drill and set in one operation makes them efficient for both new network builds and system upgrades.

Construction

In construction, digger derricks are used to drill foundation holes, lift materials into place, and support site preparation. They are especially useful on jobs that require deep or precisely positioned boreholes.

Across all of these industries, the common thread is the need for a reliable, mobile machine that can drill, lift, and place with minimal setup and maximum control. That’s exactly what a digger derrick delivers.

A digger derrick isn’t just a specialized piece of equipment — it’s a productivity tool that helps crews work smarter, safer, and faster. Whether you’re in utilities, telecom, construction, or municipal services, the benefits of using a digger derrick can be seen on every job site.

1. Increased Efficiency

Because digger derricks can drill, lift, and set in one continuous workflow, they significantly reduce the time it takes to complete a task. Crews spend less time repositioning equipment and more time getting the job done.

2. Fewer Machines Required

Instead of bringing a separate drill rig, crane, and support vehicle, a digger derrick combines multiple functions into one machine. That means fewer trucks on site, reduced fuel use, and a smaller overall footprint.

3. Improved Precision

With advanced controls and telescopic booms, operators can position loads exactly where they need to go. This is especially valuable when setting poles, drilling in tight areas, or handling heavy equipment near obstacles.

4. Lower Total Cost of Ownership

By streamlining operations and reducing the need for multiple machines, a digger derrick can lower your total project costs. When properly maintained, the equipment offers long service life and consistent performance.

5. Versatility Across Job Types

From routine maintenance to emergency response, digger derricks are suited for a wide range of applications. Their flexibility allows crews to handle different tasks without needing to switch equipment.

In short, the digger derrick is more than just a tool. It serves as a jobsite advantage that helps crews perform at a higher level. For companies aiming to boost productivity and reduce operational complexity, it continues to be one of the most valuable pieces of equipment available.

Contact the experts at Versalift today to learn more about our digger derrick solutions and discover how we can help your business operate more efficiently.

Explore related posts to learn more about Versalift’s products, customer stories, industry updates, and how we support essential infrastructure through innovation and service.

Advanced safety features like TruGuard™ and SlopeMax.

Our QA247 is the foundation of every product we assemble.

Heavyweight Performance – Best in class payloads and lighter chassis options.

We design our products with easy maintenance in mind.

Have questions about our bucket trucks or need help finding the right solution? Fill out the form below, and a member of our team will get back to you shortly.