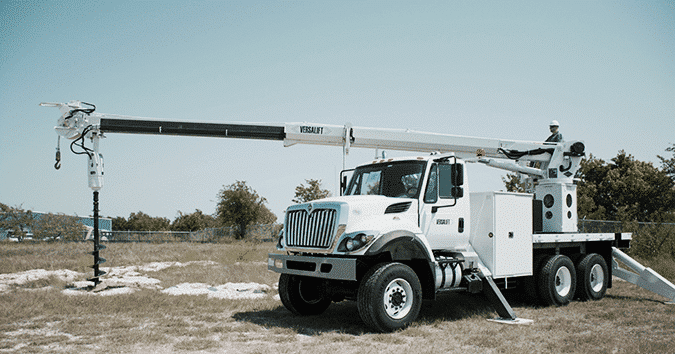

When it comes to utility work, construction, or telecom services, there’s one machine that consistently proves its worth across multiple job types: the digger derrick. Known for its ability to drill, lift, and set – all in one mobile unit – this equipment has earned a reputation as a true jobsite multitasker.

But while it’s widely recognized as a versatile tool, that flexibility also raises an important question: What specific tasks are digger derricks actually best at?

In this article, we’ll give you a clear, practical breakdown of the five job types where the digger derrick truly excels:

By understanding how this equipment performs in these areas, you can better align your equipment investments with the real-world demands of your crews – improving efficiency, reducing setup time, and enhancing jobsite safety.

Installing and removing poles – whether for power distribution, telecom networks, or municipal lighting – is one of the primary tasks for which digger derricks were originally designed. And for good reason: They combine all the steps needed to perform this job into a single workflow.

The process begins with drilling a hole using the auger system. The machine’s ability to swap out auger bits based on soil type makes it highly adaptable – whether you’re dealing with soft loam, dense clay, or rocky substrate. Once the hole is prepped, the boom and winch take over to lift and place the pole vertically. Finally, using hydraulic outriggers for stability, the operator sets the pole into place with precision.

When poles are damaged due to weather, accidents, or aging infrastructure, quick removal is just as important as installation. A digger derrick’s winch system can extract old poles vertically with minimal disruption to surrounding areas, especially when paired with proper rigging. And because the same equipment can then drill and set the replacement, downtime is drastically reduced.

Beyond utility poles, many construction and infrastructure projects require deep, reliable footings. Digger derricks equipped with high-torque augers are ideal for creating foundation holes for a range of vertical and load-bearing structures.

Whether it’s a communications tower, lighting mast, or heavy-duty signpost, structural supports require stable footing. The digger derrick’s drilling capability allows crews to bore holes quickly and accurately, reducing labor hours compared to manual or stand-alone drill rigs.

Some machines struggle when soil consistency changes from site to site, but digger derricks can be configured to handle mixed terrains. From sandy coastal zones to compacted urban backfill, operators can equip the machine with the appropriate auger heads and torque ratings to match job site conditions, ensuring safe and stable results.

Another core advantage of the digger derrick is its ability to handle heavy, often awkwardly shaped loads. While not a replacement for dedicated cranes in large-scale construction, it fills a critical niche in utility and telecom applications where moderate lifting is needed – but mobility and precision are just as important.

A typical utility job might involve not just setting poles but lifting and positioning crossarms, transformers, switchgear, or smart grid components. A digger derrick’s boom can lift these items to the necessary height, while its sheave and winch assembly ensures steady placement. This eliminates the need for an additional lifting vehicle and reduces crew coordination complexity.

Because the boom is often telescopic, multi-purpose utility vehicles provide horizontal reach that many compact cranes can’t match. This makes them especially valuable in areas where direct truck access is limited – such as behind fences, next to buildings, or across ditches. Fewer repositionings mean faster work and less wear on your vehicle.

Unlike traditional cranes, which often require a separate crew and setup process, the equipment allows a single team to load, lift, and position materials without delay. Whether you’re stringing cable in a substation, lifting a bracket assembly onto a pole, or staging materials for later installation, the machine adapts to the task.

This efficiency is particularly important in mobile operations, where crews may be required to service multiple sites in a single day. A digger derrick’s ability to transition seamlessly between digging, lifting, and setting operations helps keep the work moving and the team productive.

In projects where structural integrity is non-negotiable, digger derricks offer another hidden strength: Anchor and brace installation. These components are essential for ensuring poles and other vertical installations can withstand environmental forces like wind, vibration, and ground movement.

Most anchors are installed using helical methods that require torque and rotational control – two features that modern digger derricks handle with ease. Once the appropriate anchor is attached to the auger drive, the operator can rotate it into the ground with precision, monitoring torque levels to ensure it’s securely embedded.

In addition to utility poles, anchors and braces are often needed in semi-permanent setups like temporary lighting arrays, modular utility hubs, or event infrastructure. The speed and precision of anchor installation using a digger derrick make it a go-to choice for municipalities and contractors needing both strength and mobility.

Perhaps the most underappreciated value of this machine is the way it supports day-to-day field operations beyond installation. When working on energized or de-energized lines, these units offer a stable, safe, and versatile platform for a wide range of line construction and maintenance tasks.

Crews frequently need to swap out aging infrastructure—whether it’s changing a damaged crossarm, adding communication lines, or upgrading to smart grid hardware. Digger derricks can position equipment and personnel at the correct working height while supporting lifting tasks simultaneously. The integrated boom control allows for smooth positioning in tight quarters, minimizing risk to nearby lines or structures.

After hurricanes, ice storms, or other natural disasters, rapid response is critical. Digger derricks can be deployed quickly to clear damaged poles, reset new ones, and help restore service. Their ability to travel across difficult terrain – combined with full dig-lift-set functionality – makes them a cornerstone of storm recovery efforts.

While stringing conductor lines typically involves specialized gear, digger derricks often assist by handling pulling equipment, setting up support gear, or repositioning guide structures. This saves time on setup and allows for more compact, flexible crews in the field.

If there’s one takeaway from this breakdown, it’s this: The digger derrick is far more than a niche tool for pole setting. It’s a multi-functional machine that adds real operational value across a variety of job types – from drilling deep foundations to supporting storm response logistics.

With just one truck, you gain a system that can:

In industries where safety, precision, and efficiency are critical, a digger derrick acts as both a workhorse and a problem-solver. And when configured correctly for your specific job mix – whether that’s utility work, telecom service, or infrastructure development – it doesn’t just support your crew. It multiplies their capability.

If you still have unanswered questions, you can read our FAQ: Top Things You Need to Know About Digger Derricks

Contact our team to explore your options on digger derricks and how it can support your operations.

Explore related posts to learn more about Versalift’s products, customer stories, industry updates, and how we support essential infrastructure through innovation and service.

Advanced safety features like TruGuard™ and SlopeMax.

Our QA247 is the foundation of every product we assemble.

Heavyweight Performance – Best in class payloads and lighter chassis options.

We design our products with easy maintenance in mind.

Have questions about our bucket trucks or need help finding the right solution? Fill out the form below, and a member of our team will get back to you shortly.