A bucket truck is far more than a tool for working at height. It’s an integral part of your workflow, a mobile extension of your team, and a critical investment in safety, efficiency, and long-term performance. That’s why making the right choice goes beyond selecting a brand or a boom height. It’s about identifying a vehicle that’s purpose-built for the specific challenges your crews face every day.

The right setup can save you hours in deployment time, reduce fuel and maintenance costs, protect your team in high-risk environments, and help you meet (or exceed) industry compliance standards.

The wrong setup? It can do the opposite: Slow down operations, drive up total cost of ownership, and expose your team to unnecessary risk.

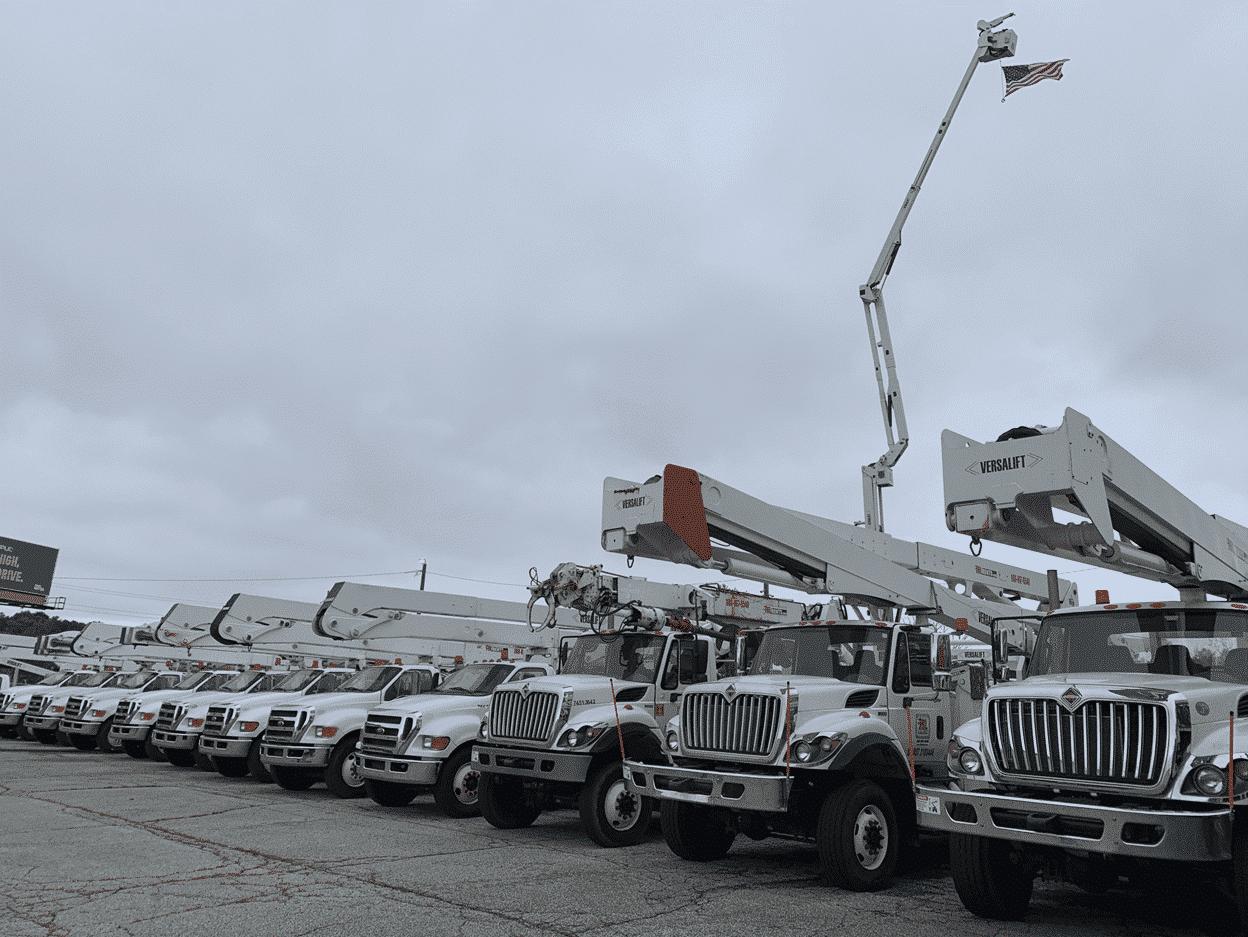

At Versalift, we engineer and manufacture bucket trucks designed with a deep understanding of the industries we serve. Whether you’re maintaining overhead power lines in remote rural areas, repairing traffic signals on busy urban streets, or trimming tree canopies in uneven terrain, our specialized industry setups are tailored to meet your exact requirements.

In this article, we’ll explore how different industries rely on customized bucket truck configurations to work safer, smarter, and more productively. Each industry has its own set of demands – and each benefits from highly specific setups:

Because in today’s fast-paced, safety-conscious, and cost-sensitive industries, choosing the right bucket truck isn’t just about lifting – it’s about elevating your entire operation.

Every worksite comes with its own challenges, and your bucket truck should be built to match them. The environments in which crews operate can vary dramatically: a dense urban intersection requires different maneuverability than a remote rural service area; a wind-swept field isn’t the same as a tree-lined suburban street. From location and terrain to the type of work being performed, industry-specific setups help ensure your equipment isn’t just functional – it’s truly fit for purpose.

Imagine navigating a tight alleyway to repair a telecom line in the city. Now imagine stabilizing a truck on uneven, sloped forest ground to remove a damaged limb from a tree. Same category of equipment – completely different requirements. Urban environments demand compact chassis, minimal tail swing, and agile booms that can extend over obstacles. Forestry or off-road conditions require 4×4 traction, extended stabilizers, and booms that can handle both vertical and horizontal outreach without compromising balance.

In industrial zones or on highways, the emphasis may shift toward visibility, rapid deployment, and ruggedness under frequent use. No single bucket truck can do it all equally well – which is exactly why configuration matters.

Safety isn’t optional, but how it’s implemented depends on what you’re working with. For electric utilities, insulated booms and dielectric protection are essential for compliance and operator safety. For telecommunications or sign installation, fall arrest anchorage, redundant control systems, and platform stability take precedence.

What qualifies as “safe” in one sector might fall short in another. Choosing a truck that’s designed for your environment ensures the right safety systems are already in place, reducing the risk of accidents, violations, and liability.

Height and horizontal outreach are often the first specs buyers look at, but functional capability goes deeper. Does your team need to lift materials as well as people? Does the job require platform rotation, tool circuits, or storage for specialty equipment? Should the truck support dual operators or offer platform-level control redundancy?

Specialized setups account for these nuances. A bucket truck used in municipal maintenance might need to carry multiple tools and offer curbside access for road safety. In contrast, a wind energy application might require maximum boom height, heavy-duty outriggers, and advanced slope sensing.

Matching your truck’s capabilities to your team’s daily tasks translates into smoother workflows, less improvisation, and better overall jobsite efficiency.

An industry-specific setup isn’t just a nice-to-have – it’s a strategic investment. While the upfront cost of a customized configuration may be slightly higher than a base model, the long-term savings are significant. A properly configured truck minimizes downtime, requires fewer workarounds, and is less likely to need costly retrofits or aftermarket add-ons.

This is where Total Cost of Ownership (TCO) becomes critical. A truck that’s easier to operate, cheaper to maintain, and better aligned with the work leads to greater productivity and fewer surprises. The wrong truck, on the other hand, can silently drain resources: more fuel, more repairs, more delays, and even safety-related shutdowns.

Learn maintenance best practices for utility trucks in order to keep TCO on a minimum: Maintenance Tips for Keeping Your Utility Truck in Top Shape

At Versalift, we work closely with customers to ensure that each unit is aligned with both their immediate needs and their long-term operational goals. Because when you choose the right setup from the start, your bucket truck becomes more than a machine – it becomes a reliable partner in your field success.

Choosing the right bucket truck isn’t just about picking a model off the shelf – it’s about finding the exact configuration that aligns with your industry, your crew, and your daily tasks. A specialized industry setup can dramatically improve safety, productivity, and long-term ROI, but only if it’s selected thoughtfully.

Here are the key factors to evaluate when buying a specialized bucket truck:

The terrain and physical space in which your crews operate should guide many of your decisions:

If your truck isn’t built for your environment, even the most advanced boom won’t deliver reliable performance.

Assess both vertical and horizontal reach:

Remember: More reach often means fewer repositionings – which translates to saved time and increased safety.

The platform itself is a workspace. Make sure it supports:

A well-equipped platform minimizes unnecessary trips to the ground and boosts efficiency per hour in the air.

Your bucket truck setup should meet or exceed current OSHA, ANSI, and DOT regulations. Look for:

Don’t assume compliance; verify it as part of your decision-making process, especially for regulated industries like utilities or telecom.

Even the best bucket truck will need maintenance. Ask yourself:

Fleet downtime is expensive. A specialized industry setup should make maintenance faster, not harder.

Price matters, but long-term value matters more. Evaluate:

Choosing a bucket truck with the right specialized setup often costs slightly more up front, but saves thousands over the life of the vehicle.

By approaching the buying process with a clear understanding of your operational needs, regulatory landscape, and long-term goals, you ensure that your next bucket truck becomes a reliable, cost-effective asset – not a compromise. At Versalift, our team helps you assess all these factors to build a configuration that’s aligned with your work, your people, and your future growth.

Want to know more about how to choose the right bucket truck? Read our article: Choosing the Right Bucket Truck for Your Business

When you invest in a bucket truck, you’re not just buying equipment – you’re choosing a long-term partner in safety, performance, and operational success. With so many industries depending on elevated work, the right configuration can make the difference between downtime and efficiency, between basic compliance and industry leadership.

At Versalift, we’ve spent decades engineering specialized industry setups that are tailored to the real-world needs of utility providers, telecom contractors, municipalities, tree care professionals, renewable energy technicians, and more. We don’t just build bucket trucks – we build solutions that fit your workflow, your crew, and your mission.

Here’s what sets Versalift apart:

When the job is critical and the conditions are demanding, your equipment should be an advantage – not a liability. A Versalift bucket truck with a specialized industry setup gives your team the tools they need to work higher, safer, and smarter.

Ready to find the right configuration for your operation?

Contact our team today to explore available options or schedule a consultation.

Explore related posts to learn more about Versalift’s products, customer stories, industry updates, and how we support essential infrastructure through innovation and service.

Advanced safety features like TruGuard™ and SlopeMax.

Our QA247 is the foundation of every product we assemble.

Heavyweight Performance – Best in class payloads and lighter chassis options.

We design our products with easy maintenance in mind.

Have questions about our bucket trucks or need help finding the right solution? Fill out the form below, and a member of our team will get back to you shortly.