Choosing the right bucket truck isn’t just about meeting operational requirements — it’s about optimizing efficiency, protecting workers, and ensuring long-term cost savings. However, with so many models and features available on the market, making the right choice can be overwhelming. In this guide, we’ll break down the key considerations to help you find the bucket truck that perfectly aligns with your business needs.

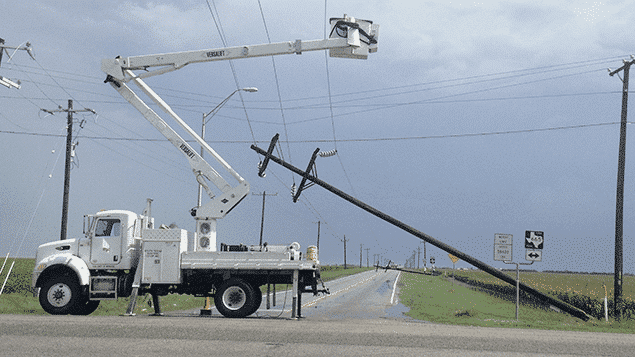

Bucket trucks are a cornerstone of many industries, making it critical to choose a model that fits the specific demands of your work. These vehicles are used for everything from maintaining power lines and installing telecommunications equipment to trimming trees and repairing signage. A truck that matches your needs can significantly improve workflow by reducing the time and effort required to complete tasks.

On the other hand, an ill-suited bucket truck can lead to inefficiencies, higher maintenance costs, and even safety hazards. For example, selecting a truck with insufficient working height may require workers to take unsafe measures to complete their tasks. Similarly, a truck with inadequate weight capacity could overload, leading to wear and tear or potential accidents.

The right bucket truck is an investment in your business’s safety, productivity, and reputation. By understanding your specific needs and carefully evaluating your options, you can make an informed decision that drives long-term success.

When selecting a bucket truck for your business, there are three key factors to consider:

One of the first and most important considerations when choosing a bucket truck is its working height. This refers to the maximum height the platform can reach, which must align with the tasks your business handles. For example, utility workers often require trucks that can extend to heights of 60 feet or more to access overhead power lines, while a signage company might only need a truck with a 30-foot reach.

It’s always a good idea to choose a truck with a working height slightly above your current needs. This ensures you’re prepared for unexpected jobs that may require extra reach. Additionally, keep in mind that working height is typically measured from the ground to the platform’s maximum extension, so the operator’s height can add a bit more range.

The weight capacity of a bucket truck is another critical factor to evaluate. This specification determines how much weight the platform can safely support, including the operator, tools, and any equipment needed for the job. Overloading the platform can not only compromise safety but also cause unnecessary wear on the truck’s components.

To determine the appropriate weight capacity, assess the heaviest load your team typically handles. It’s better to choose a truck with some buffer capacity to avoid straining the vehicle during demanding tasks. For industries like telecommunications or forestry, where heavy equipment is often required, a higher weight capacity is essential.

The environment in which your bucket truck will operate plays a significant role in determining the right model. Consider the following factors:

Understanding the conditions your bucket truck will face ensures you select a vehicle capable of performing reliably and safely.

Bucket trucks are available in diesel, gas, and electric models, each with its own set of advantages. Diesel trucks are known for their power and durability, making them ideal for heavy-duty applications and long-distance travel. Gas-powered models are generally more affordable upfront and versatile for medium-duty tasks.

Electric bucket trucks, while newer to the market, are gaining popularity for their quiet operation and environmental benefits. These models are perfect for indoor work or jobs in noise-sensitive areas like urban centers. Choosing the right fuel type depends on your business priorities, including cost, environmental considerations, and operational needs.

Safety should always be at the forefront of your decision-making process. Modern bucket trucks are equipped with a variety of features designed to protect operators and bystanders. Look for:

Investing in a truck with advanced safety features not only protects your team but also reduces liability and downtime caused by accidents. At Versalift, we have developed the SlopeMax and TruGuard™ systems that allow technicians to work in safer conditions. Slopemax is an innovative solution for safer operation on uneven surfaces, where TruGuard™ provides unprecedented security and safety for operators while working near electrical phases.

In addition to standard specifications, many bucket trucks come with optional features that can enhance performance and versatility. For example:

Choosing a truck with the right combination of features ensures you’re prepared for the demands of your industry while maximizing efficiency.

The specific requirements of your industry will largely dictate the type of bucket truck you need. Here are a few examples:

Each industry has its own unique demands, and Versalift offers a diverse range of models designed to meet these challenges.

We understand if you don’t find it sufficient to choose a bucket truck only based on a blog post like this. It is meant as a guide to help you analyze your businesses’ requirements and to narrow down your options. Therefore, we always recommend following these steps before making a decision:

Choosing the right bucket truck is a critical decision that directly impacts your business’s productivity, safety, and bottom line. By carefully considering factors like working height, weight capacity, fuel type, and safety features, you can select a truck that not only meets but exceeds your expectations.

At Versalift, we understand the importance of finding the perfect solution for your unique needs. With a wide range of industry-leading bucket trucks and a commitment to safety and innovation, we’re here to help your business reach new heights—literally.

Contact us today to learn more about our bucket truck solutions and discover how we can help your business operate more efficiently and safely.

Q: What is the most important feature to consider in a bucket truck?

A: This depends on your application. For electrical work, insulation is critical, while working height and side reach are essential for most industries.

Q: How do I determine the right size of bucket truck?

A: Assess your job site conditions. Urban areas may require smaller, maneuverable trucks, while rural or heavy-duty work can benefit from larger models.

Q: Are hybrid bucket trucks worth the investment?

A: Yes, if you work in urban areas or prioritize lower fuel consumption and quieter operation, hybrid models are an excellent option.

Q: Can I customize a bucket truck?

A: Absolutely. Most manufacturers, including Versalift, offer customizable features like storage, lighting, and power units to meet your specific needs.

Q: Why choose Versalift for bucket trucks?

A: Versalift is a trusted name in the industry, offering high-quality bucket trucks with top-tier safety, durability, and customer support.

Do you have other questions? Reach out to us.

Explore related posts to learn more about Versalift’s products, customer stories, industry updates, and how we support essential infrastructure through innovation and service.

Advanced safety features like TruGuard™ and SlopeMax.

Our QA247 is the foundation of every product we assemble.

Heavyweight Performance – Best in class payloads and lighter chassis options.

We design our products with easy maintenance in mind.

Have questions about our bucket trucks or need help finding the right solution? Fill out the form below, and a member of our team will get back to you shortly.