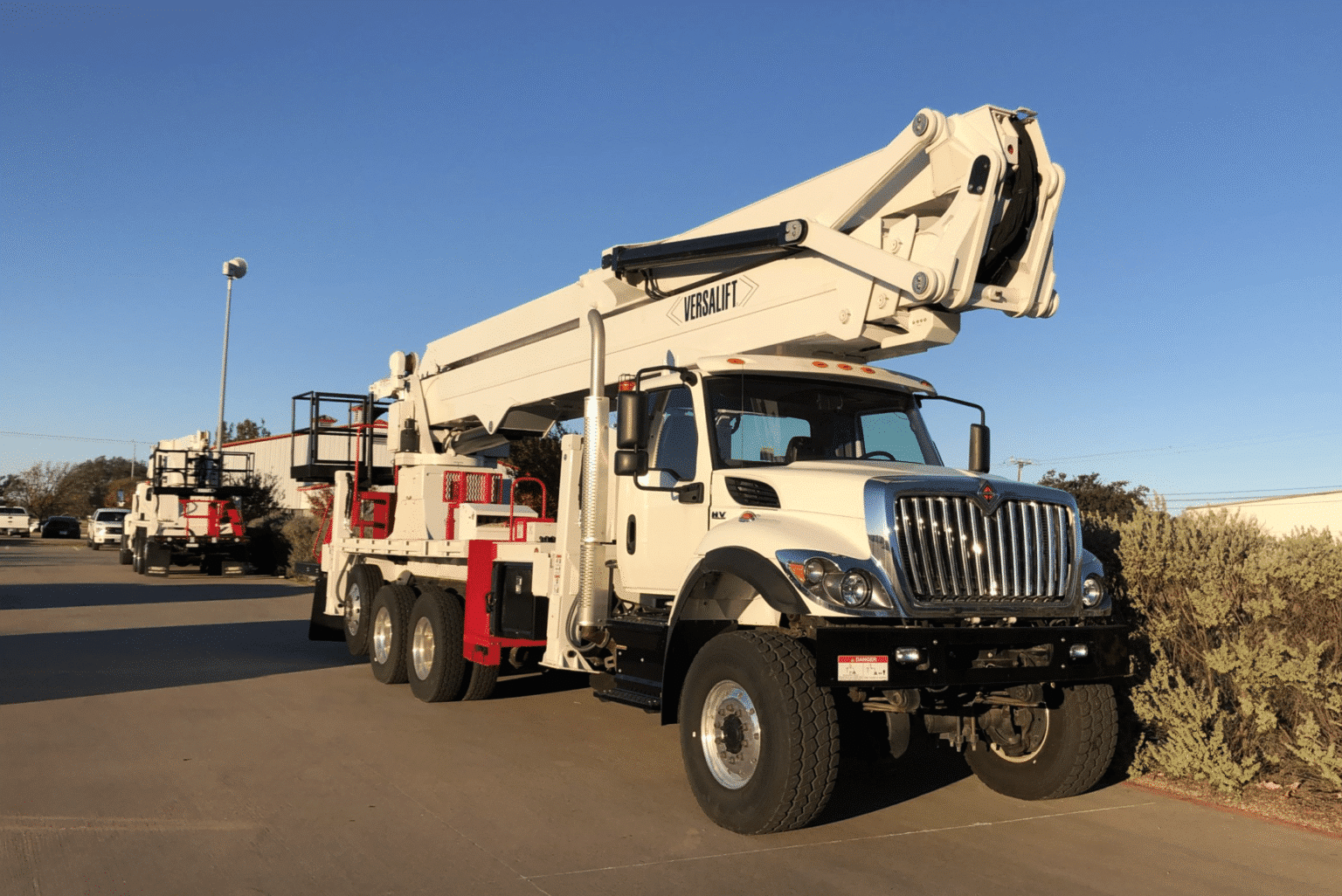

A digger derrick is a powerful, truck-mounted machine designed for lifting, drilling, and setting utility poles and other structural components. It’s one of the most versatile tools in the utility and telecommunications industries, combining several key functions into a single piece of equipment.

The core components of a digger derrick typically include:

Primary applications include:

Digger derricks are used daily by electric utility companies, telecom contractors, infrastructure crews, and municipal service providers, especially when working in remote or challenging environments.

Whether you’re operating in open fields or navigating tight urban job sites, a digger derrick allows you to dig, lift, and install – all without switching equipment. That’s what makes it such a critical asset in modern utility fleets.

Choosing the right digger derrick depends on the type of work you do, how often you do it, and the environments you operate in. While all digger derricks are designed to drill, lift, and set poles, different models offer different capabilities – and matching those to your job requirements is key to long-term performance and safety.

Here are some of the most important factors to consider:

It’s also worth thinking about crew experience, customization options, and future needs. Choosing a model that’s slightly more capable than your current baseline can give you more flexibility as project scopes evolve.

For a more detailed breakdown of how to match specifications to your application, see our full guide: How to Choose the Right Digger Derrick for Your Job.

Load charts are one of the most important tools for operating a digger derrick safely and effectively. They show how much weight the equipment can lift at different boom angles, extensions, and load radii — helping you stay within the machine’s rated limits during every lift.

Because lifting capacity changes based on how far out and how high you’re reaching, a digger derrick that can handle a heavy load up close might not be able to lift the same weight at full extension. That’s where the load chart comes in. It gives the operator a clear guide to what the machine can safely handle in different positions.

Using the load chart correctly helps you:

Most load charts are located on or near the control station of the digger derrick, and all operators should be trained in how to read and apply them. Understanding your load chart isn’t just a best practice — it’s a critical part of safe and efficient operation.

To keep your digger derrick running safely and efficiently, it’s important to follow a regular inspection and maintenance routine. How often you service the equipment depends on how much it’s used, but in general, a mix of daily checks and scheduled maintenance is the best way to prevent costly breakdowns and extend the machine’s lifespan.

Here’s a basic outline of what that looks like:

Keeping a maintenance log and addressing issues early can help you avoid bigger repairs later on. It also ensures your digger derrick stays compliant with safety standards and warranty requirements.

Yes — digger derricks are built to handle tough conditions, including cold weather, heat, and rough terrain. But to keep the equipment running smoothly and safely in extreme climates, it’s important to take a few extra precautions.

Here’s what to consider in cold weather:

In hot or dusty conditions:

With the right adjustments and maintenance routines, your digger derrick can perform reliably in almost any climate. Always refer to the manufacturer’s recommendations for temperature-specific fluids and best practices.

Explore our full range of digger derricks here.

The typical lifespan of a digger derrick depends on how it’s used, maintained, and stored. Factors that influence longevity include:

If you want to get the most out of your investment, it’s important to follow a proactive maintenance schedule and train your operators on proper use and inspection. For more detailed tips, see our related guide: [How to Extend the Lifespan of Your Digger Derrick].

Yes, all digger derricks manufactured by Versalift come with a standard manufacturer’s warranty that covers both parts and structural components. This includes:

For added protection, Versalift also offers the option to purchase an extended warranty. This option is available only to the original owner at the time of purchase and is non-transferable if the unit changes ownership.

This warranty structure is part of Versalift’s commitment to quality and reliability — helping you protect your investment and reduce long-term risk in the field.

Operating a digger derrick requires more than just experience — it requires proper training to ensure safety, efficiency, and compliance with industry standards. Because digger derricks are powerful machines used for lifting, drilling, and setting poles, operators need to be fully prepared to handle both the equipment and the jobsite environment.

Here’s what’s typically expected:

Some companies also require third-party certification, depending on the industry or the type of work being performed (for example, utility work near high-voltage lines).

Even with built-in safety features, the most important factor in preventing accidents and equipment damage is a well-trained operator.

If you didn’t find the answer you were looking for, we’re here to help. Whether you’re considering your first digger derrick or managing a full fleet, our team is ready to provide the guidance and technical support you need.

Explore related posts to learn more about Versalift’s products, customer stories, industry updates, and how we support essential infrastructure through innovation and service.

Advanced safety features like TruGuard™ and SlopeMax.

Our QA247 is the foundation of every product we assemble.

Heavyweight Performance – Best in class payloads and lighter chassis options.

We design our products with easy maintenance in mind.

Have questions about our bucket trucks or need help finding the right solution? Fill out the form below, and a member of our team will get back to you shortly.