Lifts are essential for various industries, from construction to maintenance, but improper use can lead to severe accidents. Prioritizing safety not only protects your crew but also ensures that projects are completed efficiently and without costly incidents. By continually reviewing safety practices and staying updated with the latest in safety technology, companies can foster a secure working environment that benefits everyone involved.

This guide outlines critical safety guidelines for aerial lift operations where our TruGuard and Slopemax Safety Systems are designed to make lift use even safer. Read more about the systems in this guide or click here to learn more about how we can help you ensure the highest level of safety for your crew.

Before any aerial lift operation begins, it’s crucial to assess the worksite. Evaluate the terrain, available space, and surroundings such as ditches and untamped earth fills etc. to identify potential hazards such as:

Avoiding these hazards is key to safe operation. In addition to identifying hazards, clear the surrounding area and set up visible warning signs. This not only helps the operator but also keeps bystanders and ground crew safe. Regular communication between team members is also essential for maintaining a safe environment.

Selecting the right type of aerial lift for the job is another essential step in ensuring safety. Choosing between a boom lift and a scissor lift, for instance, depends on the height and reach needed, as well as the terrain. Read more about how to choose the right aerial lift for your job here.

Before each use, every lift should be inspected thoroughly according to the Pre-Start Inspection. It is especially important to check:

To ensure the highest safety level possible, use the Versalift SlopeMax technology when operating aerial lifts. Using high-quality safety equipment (PPE) like harnesses and helmets is non-negotiable, and each operator should know how to properly use this equipment.

Do you want to take your crew’s aerial safety to another level? With our TruGuard Safety System, your crew has an improved level of protection and safety, which is especially valuable in industries like utilities, telecommunications, and construction. This system ultimately enhances job site safety, making it a valuable asset for any organization prioritizing crew protection.

Here’s why: The TruGuard Safety System is an advanced safety feature developed by Versalift specifically for aerial lift operations. Its primary purpose is to provide a higher level of electrical insulation, protecting operators from electric shocks and other electrical hazards when working near live power lines or in environments where electrical contact is a risk.

Key features of the TruGuard System include:

By incorporating TruGuard, Versalift’s lifts allow crews to work more safely around electrical hazards, preventing accidents like electric shocks. Learn more about the TruGuard system here.

Aerial lifts should only be operated by trained and qualified personnel. Operators must complete the required training and hold a separate certificate of completion for each different unit that he/she operates per ANSI 92.2 to ensure they are cable of using the equipment safely and effectively.

Regularly updated training is also important as it ensures operators stay current with any new safety protocols, technological advances, and lift functionalities, such as those provided by Versalift. This kind of training reinforces good habits and prepares the crew for any situation they might encounter.

Weather can greatly impact the safe operation of aerial lifts. Wind, rain, and frost are especially concerning as they can destabilize equipment and reduce visibility.

Operators should be prepared to pause or reschedule work in adverse weather conditions. When work must continue outdoors, specific precautions should be taken. For example, if strong winds are expected, make sure that the lift is properly secured and any additional equipment on the platform is safely stowed.

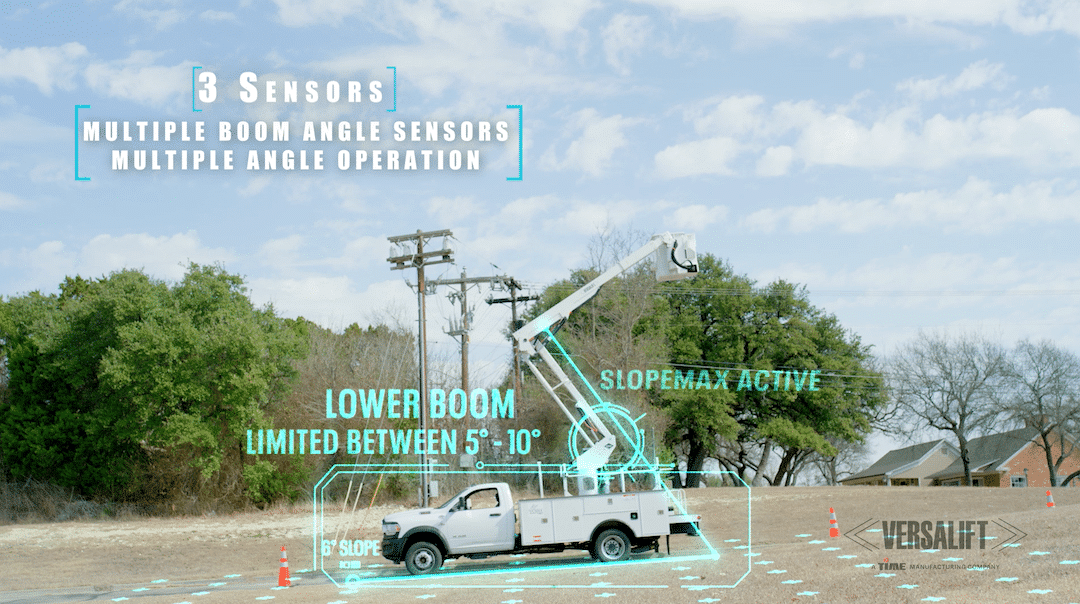

Our Slopemax technology also assists in maintaining stability by allowing lifts to operate safely on inclined surfaces. Slopemax is designed to adjust and stabilize the lift even on slopes, reducing the risk of tipping over. This feature is especially beneficial for outdoor jobs on uneven terrain, ensuring the platform remains level and safe.

According to aerial lift guidelines, it is officially recommended that bucket trucks are limited to working on slopes of up to five degrees. However, with our Slopemax technology, it is safe to operate on a base slope of greater than five degrees, e.g. on steep hills or uneven terrain. Slopemax allows operators to work on slopes of five to ten degrees without compromising safety – albeit with a reduced lower boom function in some cases.

Following established safety protocols during lift operation is essential. Operators should be careful when raising or lowering the lift and must always stay connected to their harness. Overloading the lift can be hazardous, so make sure it’s used within its weight limits.

Communication between the operator and ground crew is crucial for coordinating movements and ensuring the safety of everyone on-site. Clear hand signals or radios should be used, especially in noisy environments.

While following safety guidelines reduces the likelihood of accidents, emergency preparedness is also essential. Utilize the Operators Manual for Emergency Operations and conduct regular drills so that everyone knows what to do if an accident occurs.

Regularly review and update these protocols to account for any new equipment or changes in the work environment.

By following a set of best practices, companies can minimize risks and protect their crews. Do you want to learn more about the TruGuard and Slopemax systems? Reach out to us here.

Explore related posts to learn more about Versalift’s products, customer stories, industry updates, and how we support essential infrastructure through innovation and service.

Advanced safety features like TruGuard™ and SlopeMax.

Our QA247 is the foundation of every product we assemble.

Heavyweight Performance – Best in class payloads and lighter chassis options.

We design our products with easy maintenance in mind.

Have questions about our bucket trucks or need help finding the right solution? Fill out the form below, and a member of our team will get back to you shortly.