Before starting any job with a bucket truck, it’s vital to carry out a thorough inspection of both the truck and the surrounding work environment:

It is a ‘no brainer’ that only trained and certified personnel should operate bucket trucks. Operating a bucket truck without proper training is not only dangerous for the operator but also for nearby workers, civilians and property. Qualified operators must understand how to handle the controls, recognize common risks, and follow established safety protocols.

Additionally, ensuring that operators adhere to industry standards, such as ANSI or OSHA (Occupational Safety and Health Administration) regulations, is crucial. These guidelines are designed to minimize accidents and ensure a high level of safety for both operators and ground workers.

Once the pre-operation checks are complete, it’s time to focus on the best practices during bucket truck use. First and foremost, operators should follow all manufacturer guidelines and never exceed the load capacity of the bucket. Maintaining clear communication with ground personnel and being aware of the surroundings at all times is also essential.

Following these safety protocols during operation can significantly reduce risks:

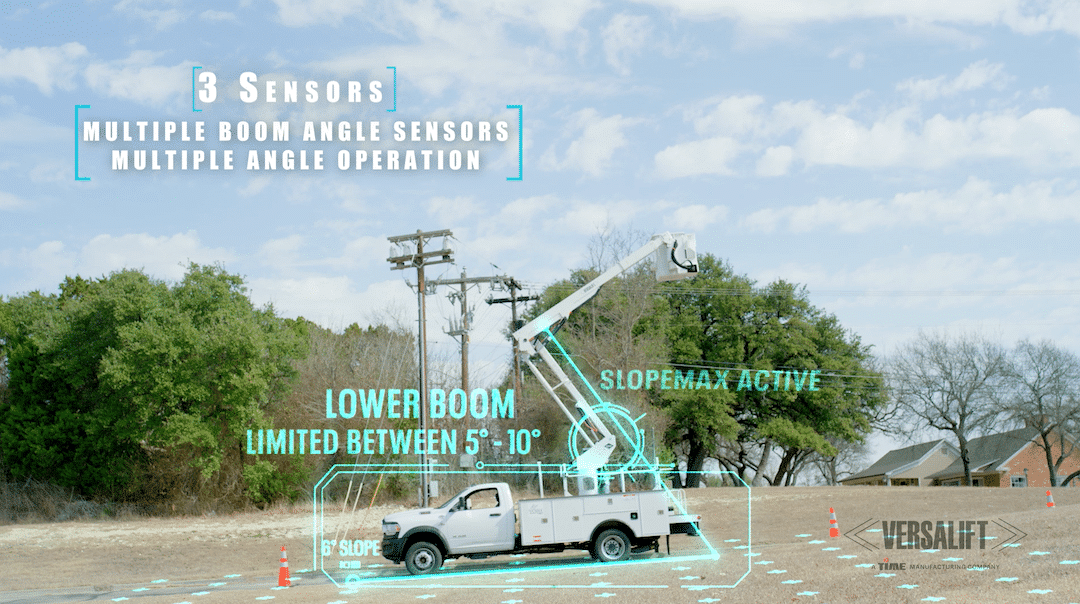

Besides being mindful of these best practices, you should also consider adding Slopemax to your safety measures – especially if your crew is working on uneven terrain.

SlopeMax is an innovative passive safety system that improves both operator safety and job site efficiency. The advantages of SlopeMax will be felt most by fleets and contractors that operate in hilly and mountainous areas, where the slope of the job site exceeds five degrees. SlopeMax by Versalift increases your productivity, and it decreases any operator’s capacity to use a bucket truck in an unsafe or illegal way.

Read more about safety for operating bucket trucks here.

Working near power lines introduces an additional layer of danger. Bucket truck operators must be especially cautious when operating in areas with live electrical lines.

If you wish to provide your crew with an extra level of safety when working in heights near power lines, consider Versalift TruGuard. TruGuard is an advanced safety feature developed by Versalift specifically for aerial lift operations. Its primary purpose is to provide a higher level of electrical insulation, protecting operators from electric shocks and other electrical hazards when working near live power lines or in environments where electrical contact is a risk.

In the event of an emergency, such as equipment failure or electrical contact, quick thinking and preparation are crucial. Ensure all operators and crew members know how to activate emergency controls and are trained to respond to a variety of potential emergencies.

Once the job is complete, there are still important safety measures to follow.

Operating a bucket truck safely requires attention to detail and a commitment to following best practices. From pre-operation inspections to safe shutdown procedures, every step in the process is critical to preventing accidents and ensuring a productive workday. Always prioritize safety and remain vigilant about following industry standards and regulations.

By staying proactive about safety, bucket truck operators can minimize risks and protect both themselves and those around them on the job.

Do you want to learn more? Reach out to us here.

Explore related posts to learn more about Versalift’s products, customer stories, industry updates, and how we support essential infrastructure through innovation and service.

Advanced safety features like TruGuard™ and SlopeMax.

Our QA247 is the foundation of every product we assemble.

Heavyweight Performance – Best in class payloads and lighter chassis options.

We design our products with easy maintenance in mind.

Have questions about our bucket trucks or need help finding the right solution? Fill out the form below, and a member of our team will get back to you shortly.