Overcenter

Overcenter Bucket Trucks for Demanding Industries

Versalift overcenter bucket trucks are engineered for smarter design, reliable performance, and versatile applications. Built and upfitted to spec, they meet the unique needs of fleets across industries.

Popular in the forestry industry, overcenter units are available in both rear-mounted and standard forestry configurations. They also deliver proven value to construction, electric utility, and municipal fleets.

Industries Served by Overcenter Bucket Trucks

Versalift overcenter bucket trucks provide safe, reliable access for crews working across a wide range of industries, including:

- Telecommunications – Building, expanding, and maintaining communication networks.

- Utilities – Supporting daily service, repairs, and maintenance.

- Transmission – Handling high-voltage line construction and long-distance projects.

- Distribution – Delivering reliable access for local power distribution systems.

- Tree Care – Providing arborists with reach and maneuverability in challenging environments.

- Sign, Light & Traffic – Installing and servicing signage, streetlights, and traffic signals.

Why Choose Versalift Overcenter Bucket Trucks

Choosing an overcenter unit means investing in equipment that protects operators, minimizes downtime, and adapts to diverse job requirements. These features highlight why fleets across industries rely on our overcenter lifts.

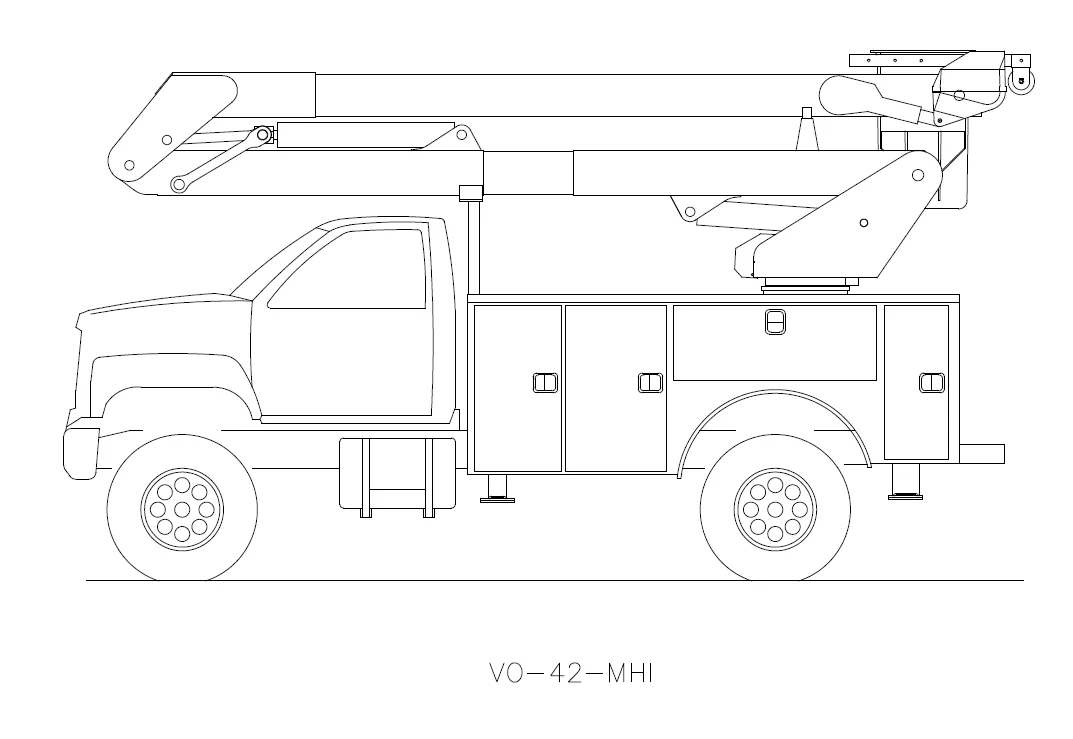

Operator Safety at the Platform

Every insulated overcenter unit includes TruGuard® and Electroguard® safety systems, delivering advanced lineman protection. Greater maneuverability and side reach enhance efficiency and reduce time on the job.

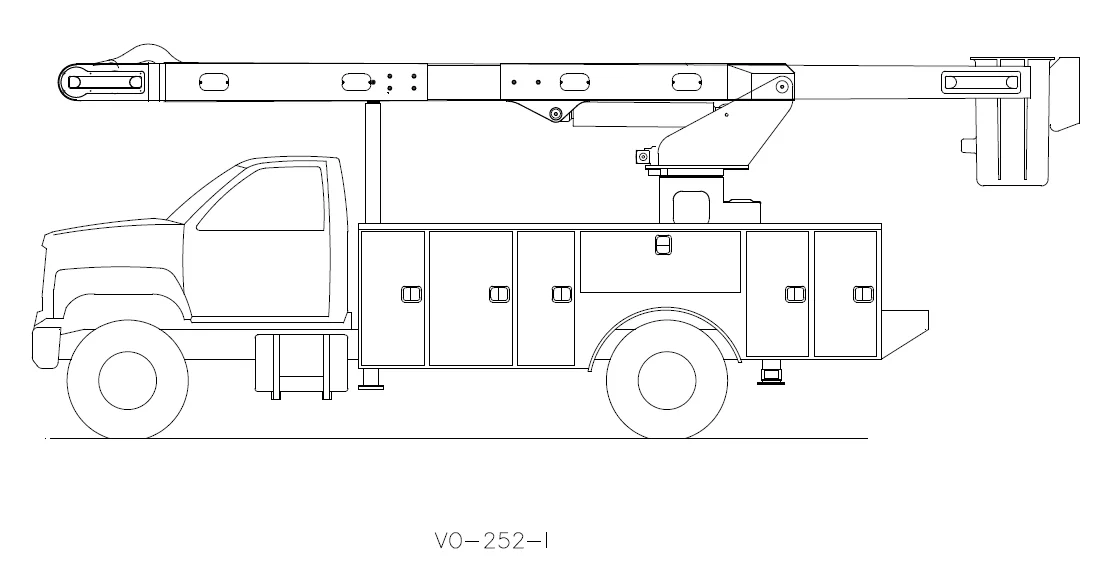

Lightweight Maneuverability

- High tensile strength, low-weight steel in boom construction

- Single lift cylinder at the knuckle reduces weight

- Hydraulic outrigger valves ensure dependable deployment

- Lower stowed travel height improves clearance

- One-piece upper control guards allow debris to escape

Dependability & Uptime

Versalift overcenter aerial devices are designed for low maintenance and maximum uptime. Easy service access and proven engineering minimize downtime, making them a trusted choice for utilities, municipalities, forestry, and construction fleets.

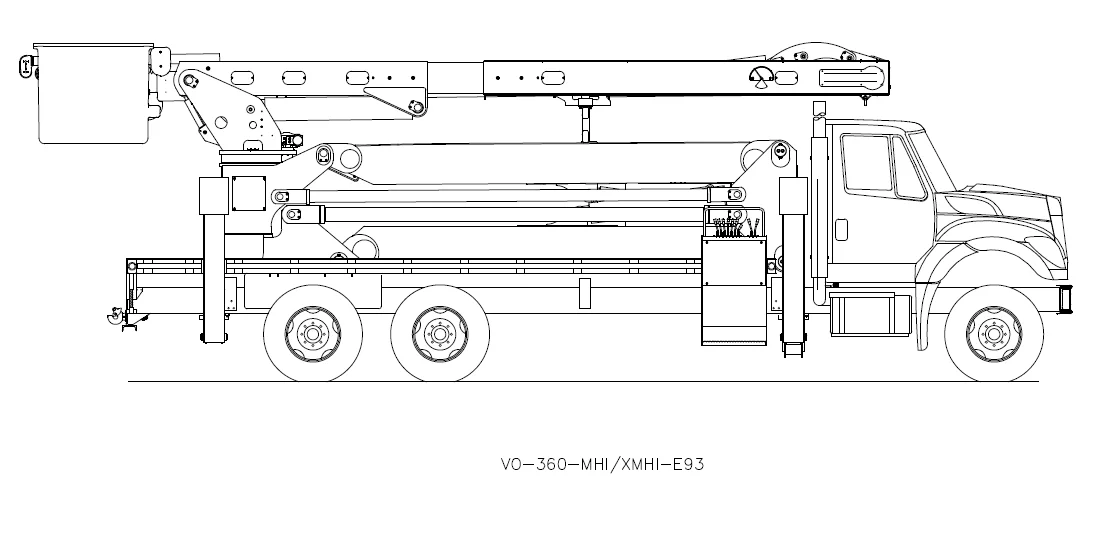

Versatility on the Jobsite

High payload capacity, responsive full-pressure hydraulic upper controls, and a boom that can be moved to several working positions without relocating the truck make Versalift overcenter units highly efficient in open construction and industrial settings.

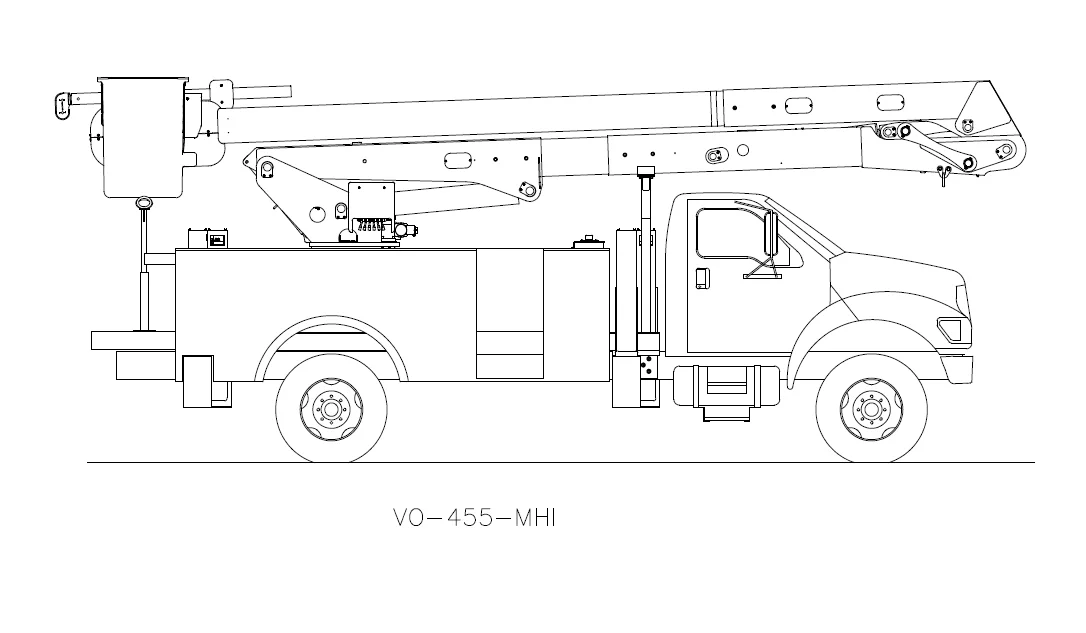

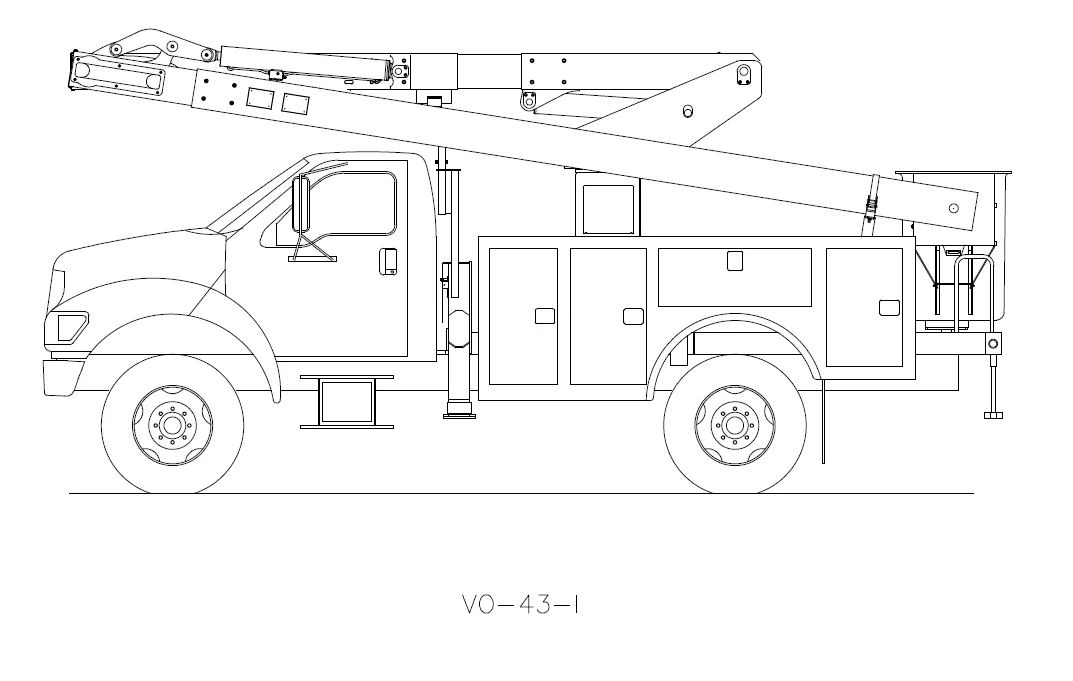

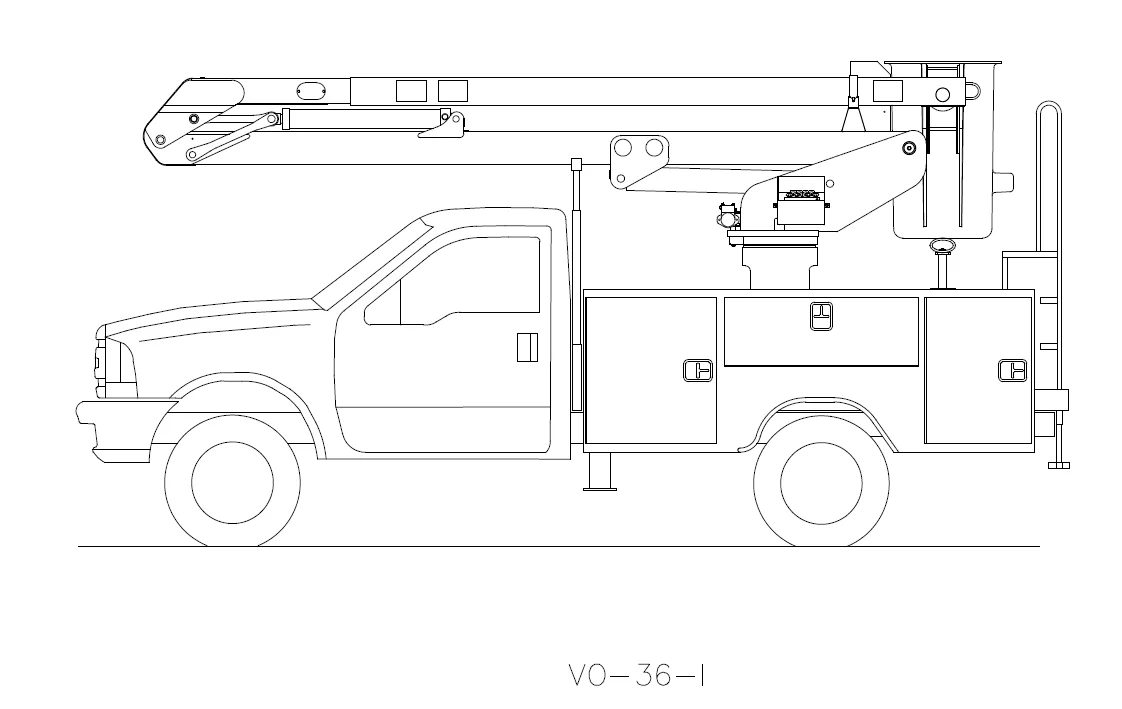

Customized Overcenter Bucket Trucks

At Versalift, every overcenter bucket truck is hand-built with precision. Since 1965, we have combined craftsmanship with innovation. The result is equipment that meets rigorous safety and durability standards.

Our team works closely with you to design and configure the features, options, and working envelopes that match your fleet’s needs. Whether for forestry, utilities, or construction, your overcenter unit is built to support your goals and keep crews productive for years to come.

Unique Versalift Features

From engineering to everyday use, Versalift builds in features that help crews work more efficiently while keeping operating costs low.

Lower True Cost of Ownership

Engineered to the highest standards, Versalift bucket trucks feature smarter, more reliable design that delivers a lower total cost of ownership across fleets.

Full Service Provider

With more than 250 service locations in North America, rental fleet coverage, and competitive equipment financing, Versalift distributors provide a complete fleet solution.

Ease of Maintenance

Versalift equipment spends more time in the field and less time in the shop. Non-lube lift bearings require little maintenance and are designed to last the practical life of the truck. Plus, our aerial lifts have no mandatory tear-downs.

Attention to Detail

Every unit reflects Versalift’s commitment to quality:

- Torque striping marks all critical bolts for quick, daily visual inspections.

- Every critical pin has a redundant pin set, which is also torque-striped for added safety.

Talk to a Versalift expert to learn how overcenter bucket trucks can strengthen your fleet with greater safety, reliability, and uptime.

Versatile Aerial Lifts Tailored for Your Industry

From utilities and telecommunications to tree care, signage, and wind energy—Versalift® builds aerial lifts that match the unique needs of your industry.

With proven reliability and the lowest true cost of ownership, our equipment keeps your teams working safely and efficiently.

Forestry & Tree Care

Specialized lifts for safe tree care applications

Explore our products

Sign, Light & Traffic

Efficient access for signs, lighting, and traffic systems

Explore our products

Tele-communications

Bucket trucks for maintaining telecommunications networks

Explore our products

Municipalities

Trusted fleet solutions for local infrastructure needs

Explore our products

Safety First

Advanced safety features like TruGuard™ and SlopeMax.

Quality Assurance

Our QA247 is the foundation of every product we assemble.

Lighter Build

Heavyweight Performance – Best in class payloads and lighter chassis options.

Easy to Service

We design our products with easy maintenance in mind.