Wind Energy

Bucket Trucks and The Wind Energy Industry

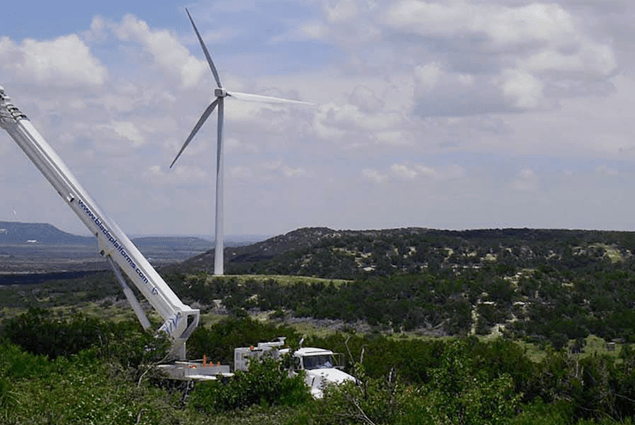

The wind energy industry has added significant power generating capacity over the past few years, and is currently generating 8.5% of all electricity in the United States. The industry itself is increasingly reliant upon truck-mounted aerial lifts to maintain the continuing safe and effective operation of wind turbines. This is because they are so much more efficient than other methods for hub heights of 95 meters. Annual maintenance, cleaning and inspection must occur on every blade, on every turbine, in North America, and around the world. Ruthmann offers the most economical high access platform for wind turbine maintenance in North America.

Working Height

243 ft (74 m) - 295 ft (90 m)

Height to Bottom of Platform

238 ft (72.5 m) - 290 ft (88.4 m)

Horizontal Reach

121 ft (37 m) - 137 ft (41.8 m)

Stowed Travel Height

13.5 ft (3.96 m)

Platform Capacity

1,300 lbs (590 kg)

Platform Rotation

180º

Insulated/Non-insulated

Insulated

Material Handling

Yes

Explore Our Full Lift Range

Find a Dealer Near You

Compare Lift Models

Check Warranty Details

Ruthmann is a Time Manufacturing Company

Ruthmann Aerial Lifts for Wind Turbine Maintenance

Highly stable in windy conditions (up to 12.5 meters/second), at full working height and load, Ruthmann high access aerial work platforms allow for the efficient maintenance of wind turbines and blades. Ruthmann equipment can be set up and stowed very quickly and are designed to return to their stowed traveling position in minutes. Aerial lifts are as many as six times more efficient and productive than yesterday’s conventional approaches to wind turbine blade maintenance. The basket capacity of Ruthmann t-243 and T-295 units makes efficient and effective blade repair and maintenance possible. These aerial lifts are perhaps the most effective tools currently available for the inspection and maintenance of wind turbines and blades.

Innovation at the Highest Elevation

With a well earned reputation for designing premium high reach work platforms, Ruthmann is dedicated to supporting rental fleet and wind farm service customers in the wind energy industry. Ruthmann, based in Germany, supports wind energy maintenance fleets all around the world. At heights approaching 300 feet, it is essential that wind turbine service technicians are confident in their equipment.

Wind turbines run all day, and all year long, except when the wind isn’t blowing, and when they are being serviced. While they work at generating power all year, wind turbines and blades have a maintenance service season that lasts approximately seven months. As a result, it is important to identify other applications for these high access aerial work platforms.

Other industries use Ruthmann high access equipment.

Industries include petrochemical inspection and maintenance, utility line construction, building inspection and maintenance, bridge inspection from below, high-elevation sign work, and the very high-profile space industry.

Ruthmann: Wind Turbine Maintenance & Inspection Platforms

T-243A-HF

The Ruthmann T-243A-HF has several advantages when compared with similar height products. With a 75 meter working height, technicians are able to work the blades on a 95 meter tower. This is not possible in the case of competing products whose reach only extends to 70 or 72 meters. Ruthmann 75 meter bridge inspection units are much easier to maneuver than 90 meter units because they are smaller, and have a lower price tag.

T-295A-HF

The Ruthmann T-295A-HF is a wind turbine and blade maintenance work platform with a 90 meter working height. The 90 meter working height is 295.’ One unique advantage of this unit is that it has easily the greatest side reach in the industry. Comparable height products have limited side reach of up to 32 meters (approximately 100′), while the Ruthmann T-295A-HF has much more horizontal reach, at 41 meters (137’).

Ruthmann Equipment Efficiently Supports Wind Farms

With 200 working days per year, one high reach aerial work platform can service and maintain 200 turbines. This amounts to approximately one wind turbine per day. If a wind farm has 1,000 turbines, which is not unreasonable, it can justify the expense of owning its own high access work platforms. With that said, established wind farms tend to engage in long-term lease agreements that include a service clause, equipment training and readily deployed service engineers. In long term leases, equipment can be rented with or without an operator. In the United States, individual wind farms tend to take their own approaches.

Versalift Equipment for Wind Turbine Blade Maintenance

Versalift Customer Service

Customer service is a point of pride within our family of distributors, and we all take ownership in providing it. We have grown to become a global leader in safety, reliability and overall quality in aerial lifts because we pay attention to detail and we take the time to put our customers first. We listen to you so that we can understand your concerns, and get you back on your way to the job as efficiently as possible. Our Versalift Global Partner Portal (VGPP) and Versalift FIT online operator training programs allow each of our customers to manage, support and maintain their aerial lifts from a desktop computer, tablet, or smartphone. When using the VGPP, customers can access their aerial lift manual, order parts, schedule a maintenance call, or speak directly with a Versalift service representative.

Greater Stability, More Safety, Game-changing Efficiency

Highly stable in windy conditions (12.5 meters/second), at full working height and load, the Ruthmann aerial lift allows for work to continue efficiently. Ruthmann equipment stows very quickly: following notification of incoming inclement weather conditions, Ruthmann higher-reach wind energy aerial lifts are designed to return to their stowed travelling position in minutes. Also, these aerial lifts are as many as six times more efficient and productive than yesterday’s conventional approaches to wind turbine blade maintenance.

UNIQUE RUTHMANN FEATURES

- Industry-leading side reachAlthough industry-leading side reach is not applicable to wind turbine and blade maintenance, side reach is essential to construction, plant maintenance and dozens of other commercial applications

- Working Height : Gross WeightInterstate travel and transport are made accessible with Ruthmann aerial lifts, with exceptional working height to gross weight ratios

- Spacious working platformRuthmann lifts can accommodate as many as seven technicians in one flight

- Stability at maximum heightLike Versalift, Ruthmann has earned its reputation for beautifully engineered aerial lifts

About Versalift

As the industry quality leader in bucket trucks, Versalift also manufacturers aerial devices, digger derricks and other specialty equipment for power generation, transmission and distribution, investor-owned utility, telecommunication, light & sign, and tree care industries. Working with co-ops, municipalities, government agencies and corporations through its global network of facilities and family of distributors, the company manufactures, sells and services bucket trucks in North America, South America, and Europe and employs nearly 700 associates worldwide. For further information about telescopic articulated bucket trucks please contact us at sales@versalift.com.