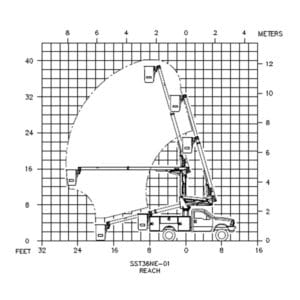

VERSALIFT SST-36-NE a non-insulated, end mounted 35 ft. 6 in. (10.8 m) telescopic articulating aerial platform lift, 40 ft. 6 in. (12.3 m) working height including the following standard and optional features:

- Standard platform capacity of 350 lbs. (158.7 kg)

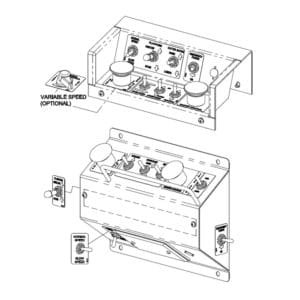

- Upper controls consist of a series of spring-loaded toggle switches and a master control switch

- Engine start/stop system with controls at platform and remote handheld lower controls

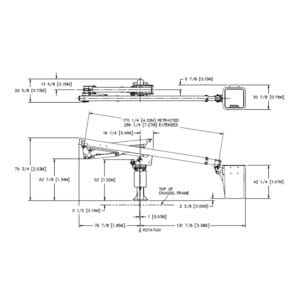

- 370° non-continuous rotation with a mechanical stop

- Open center hydraulic system operates at 1.5 to 2 GPM (6-8 LPM) at 2000 psi (140 kg/cm)

- External hydraulic oil reservoir with 6 gal. (23 l) capacity

- Outer boom consists of a 6 in. X 8 in. (150 mm x 200 mm) steel section

- 5 in. X 7 In. (130 mm x 180 mm) rectangular aluminum inner boom housed within the outer boom

- End mounted walk in 24 in. x 30 in. x 42 in. (0.61 m x 0.76 m x 1.07 m) fiberglass platform

- Manual rotator for platform

- Master/slave hydraulic leveling with upper control to tilt for cleanout or rescue

- Non‑lube bearings used at all pivot points

- Multi‑link hose carrier system through booms

- Rubberized boom cradle

- 12 Volt DC backup pump providing power to all boom functions

- Mounting hardware for chassis/cab installation

- Handheld remote lower control with series of spring-loaded toggle switches and control selector switch

- GFCI receptacle for 120 Volt power at platform

- Full body harness and lanyard

- Painted standard white urethane

- Two operator’s manuals and two service manuals

- ANSI A92.2 data plate

Steel Service Body 108” Long x 40” High x 94” Wide:

- Removable composite tailboard installed at rear

- 30” tread plate tail shelf with 7-lamp light bar installed

- Master locking system

Curb side compartments:

- 1st Vertical: Two (2) adjustable shelves with dividers

- Horizontal: Open

- Rear Vertical: Two (2) adjustable shelves with dividers

Street Side Compartments:

- 1st Vertical: Two (2) adjustable shelves with dividers

- Horizontal: One (1) removable shelf with dividers

- Rear Vertical: Five (5) fixed material hooks (1-3-1)

Cab and chassis to the following specifications:

- 2024 Dodge 4500 4×2 cab and chassis with a 60” cab to axle

- 22,500 lb. GVWR

- 6.4L V8 heavy duty HEMI gasoline engine

- Allison 6-speed automatic transmission

- 225/70R19.5G Load Range H HDR+

- Air Conditioning

- 7″ Color Touch Panel Display

- Power equipment package includes power windows, door locks and remote keyless entry

- Radio: AM/FM stereo w/ Bluetooth

- Trailer brake controller

- Rear view camera

- Painted Winter White

Installation to include the following:

- Install VERSALIFT SST-36-NE, mounting hardware, and PTO and pump

- Install rear torsion bar

- Install and paint service body and accessories

- Install ladder rack with hold down and locking feature

- Install two (2) amber strobe lights in tail shelf and two (2) strobes lights in front grill

- Install 2000-watt inverter with battery and box (curbside front compartment)

- Install combination pintle hitch with 2” ball, D rings and 7 prong trailer connector

- Install mud flaps, back up alarm and park brake interlock system

- Furnish fire extinguisher, 3-piece triangle reflector kit and pair of rubber wheel chocks

- Test ride completed unit for 1 hour

- Test and certify per ANSI A92.2