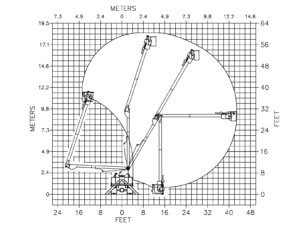

VERSALIFT VN-555-MHI insulated 55’ 3” non-over center, articulated aerial platform lift with a 60’ 3” working height, including:

- Standard platform capacity 700 lbs. (317 kg).

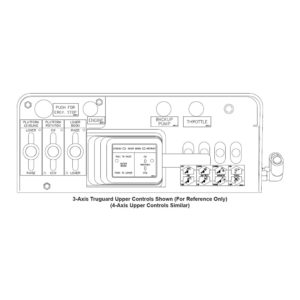

- UNITROL single stick mounted on curbside between boom and platform with integral safety trigger and emergency stop control.

- Primary TruGuard dielectric isolating system with single stick control. All control handles are isolated and tested per ANSI 92.2. The high resistive dielectric system is protected from direct environmental and job-related contamination. TruGuard technology incorporates the use of full hydraulic controls with durable metal handles and linkages.

- Automatic throttle control activates with trigger at single stick.

- Full pressure turret mounted controls with override.

- Engine start/stop from platform and lower controls.

- Auto throttle disable valve at platform.

- Continuous rotation including 3 slip rings.

- Open center hydraulic system providing 8 to 12 GPM (30-45 LPM) and 3000 psi (210 kg/cm²) system pressure.

- 5 ft. (1.98 m) jib and winch with 2000 lbs. (905 kg) capacity. Hydraulic jib articulation and extension is included. Includes 75 ft. (22.8 m) of 9/16-inch (14 mm) diameter synthetic load-line.

- Lift eye on lower boom with 2500 lbs. (1125 kg) capacity.

- 90° hydraulic platform rotation with hydraulic tilt for cleanout or rescue.

- Fiberglass upper boom tested per ANSI A92.2 for Category C 46-KV and below.

- Lower boom articulation 120° with upper boom articulation 192° relative to lower boom

- Vacuum flashover prevention system.

- Chassis insulating system (lower boom insert) providing 18” insulation gap including accommodations to bridge insulation gap for testing per ANSI A92.2

- White urethane over white gel coat on fiberglass upper boom and lower boom insert.

- Two (2) sets of hydraulic tool outlets at platform with 2000 psi reducing valve.

- Two (2) ½” diameter return lines.

- External reservoir with a 30-gallon (110 L) capacity and sight level gauge.

- Dual A-frame outriggers with 158 (4.0 m) spread with outrigger boom interlock system.

- Automatic boom latch. The rotary auto boom latch works off the lift hydraulic pressure to open and close.

- Full length sub frame and mounting hardware for cab and chassis.

- Standard Time white paint.

- Two safety harnesses and lanyards

- Two (2) operators and two (2) service manuals.

- Manufactured and tested per ANSI A92.2

- Continuous rotation with engine start/stop and 12 volt backup pump.

- One (1) two-man 24” x 48” x 42” deep closed fiberglass basket with two steps.

- Vinyl platform cover and liner for 24 in. x 48 in. x 42 in. platform.

Cab and chassis specifications include the following:

- Freightliner M2 106 4X4 cab and chassis

- Cummins B6.7 325HP diesel engine

- Allison 3500 RDS automatic transmission

- 33,000 lb. GVWR: 14,000 lb. front GAWR (14,600 lb. suspension) and 21,000 lb. rear GAWR (23,000 lb. suspension)

- 22.5×8.25 painted steel disc wheels with 11R22.5 tires

- 120 inch C.A.

- Engine block heater with socket located below driver’s door

- Air brake system

- Back up alarm

- Air conditioning

- AM/FM radio

- Painted White Elite

- Full specifications available upon request

156 in. x 48 in. x 94 in. line body including the following:

- Stainless steel automotive rotary type door latches and hinges

- Chain stops on all doors

- Rubber rolled crown type fenders and automotive bulb type weather stripping

- Master door lock system

- Outrigger pad storage holders with pendulum retainers

Street side compartments:

- 1st vertical: 24 in. – Five (5) fixed material hooks (1-3-1)

- 2nd vertical: 24 in. – Two (2) adjustable shelves with dividers

- 3rd vertical: 24 in. – Two (2) adjustable shelves with dividers

- Horizontal: 60 in. – Adjustable dividers installed in compartment bottom

- Rear vertical: 24 in. – Two (2) adjustable shelves with dividers

- Hot stick shelf: 156 in. long with rear dropdown access door

Curbside compartments:

- 1st vertical: 24 in. – Five (5) fixed material hooks (1-3-1)

- 2nd vertical: 24 in. – Tread plate access steps to bed area with grab handle on each side

- 3rd vertical: 24 in. – Two (2) adjustable shelves with dividers

- Horizontal: 60 in. – One (1) removable divider shelf with dividers

- Rear vertical: 24 in. – Five (5) fixed material hooks (1-3-1)

- Ladder Rack: 132” x 3” x 20” horizontal ladder rack with rear roller and tie down loops

- Tail shelf: 30 in. tread plate tail shelf

- Rear lighting: Lamp light bar installed at rear of tail shelf and rubber mounted recessed rear lighting kit with incandescent lights

- Wheel chock storage: – One (1) each side built into wheel wells

Installation includes the following

- Install VERSALIFT VN-555-MHI, mounting hardware, PTO, and pump

- Install and paint Line Body and accessories

- Install main and auxiliary A-frame outriggers with interlock system

- Install BP-100A pintle hitch, reinforcements, and 7 prong trailer connector

- Install two (2) strobe lights in front grill and two (2) amber strobe lights in rear tailshelf

- Install mud flaps, outrigger pad holders, slope indicators, access steps and handrails

- Relocate glad hands to rear of chassis

- Install grounding kit system, park brake interlock system and quick disconnect fittings

- Paint black non-skid on body floor

- Furnish outrigger pads, wheel chocks, fire extinguisher, and 3-piece triangle reflector kit

- Test ride completed unit for one (1) hour

- Test and certify per ANSI A92.2