Increasing operational efficiency by reducing costs and waste

Reaching new customers

Increasing competitive advantage

Protecting and strengthening brand

Planning for long-term business viability and success

Responding proactively to regulatory constraints and opportunities

Around the world, companies that are engaged in sustainability efforts come in all shapes, sizes, ages and sectors. Manufacturing companies can move toward greater sustainability simply by improving their operational efficiency, which reduces waste, and improves the bottom line. Time Manufacturing Company has a stated goal of zero defects and 100% first time product quality (FTQ), continuing to optimize operational efficiencies and, as a result, reduce waste.

“Time Manufacturing Company is doing everything possible to provide products that have a carbon neutral footprint like lightweight truck bodies, the ePTO and electric/hybrid chassis. We have equipment that is designed and developed to maintain wind energy generators, something that is important to reduce our carbon footprint. It is important for our company to support that type of industry to be carbon neutral to protect our planet. Because it’s not just for us. There are other generations coming along, and we have to think about that.” – James Christian, VP Engineering, Time Manufacturing Company

In the United States, electric utility distribution is managed by investor-owned utility companies (IOUs), electric cooperatives, and public utilities. When they are public companies, IOUs are required to report to their investors on the steps they have taken toward sustainable operations. Time Manufacturing Company brands serve a wide variety of electric utility companies and fleets, both in the United States and around the world. We benefit from viewing these concerns, which electric utilities must address, as a way to create value for our customers.

Renewable Energy, Waste Management And Carbon Emissions

Three important environmental factors upon which publicly traded electric utilities must report are how they are exploring Opportunities in Renewable Energy, and how Toxic Emissions and Waste and Carbon Emissions are managed in their supply chains.

Wind turbines are generating renewable energy at an extremely efficient rate, and they are an important part of American energy independence. The states of Texas and Oklahoma, which are perhaps best known as big oil states, also happen to be the nation’s leaders in wind-generated electricity. This is not an accident: wind-generated electricity is currently the most efficient application of renewable energy generation. Time Manufacturing Company supports the wind-powered electricity generation industry in the United States, and around the world, selling and servicing Versalift and Ruthmann high access work platforms to organizations across Europe, Africa, Asia and the Americas. Versalift and Ruthmann high reach aerial lifts play a significant role in the wind energy industry. Wind farms rely on the stability and safety of these high reach aerial lifts to install, maintain and repair wind turbines and blades.

Electric utility organizations are also measured by how toxic emissions and waste are addressed across their supply chains. Strong environmental management systems include procedures for the responsible handling of toxic waste (Non-RCRA & UWM) resulting from manufacturing operations, water pollution prevention (SWPP), and spill prevention (SPCC) programs. At Time Manufacturing Company:

Since electric utility providers are heavily measured by their carbon emissions, it is important to show how Time Manufacturing Company works hard to be an environmentally responsible manufacturer across all of its brands. Time Manufacturing Company brands have created product Integrations which support emissions goals.

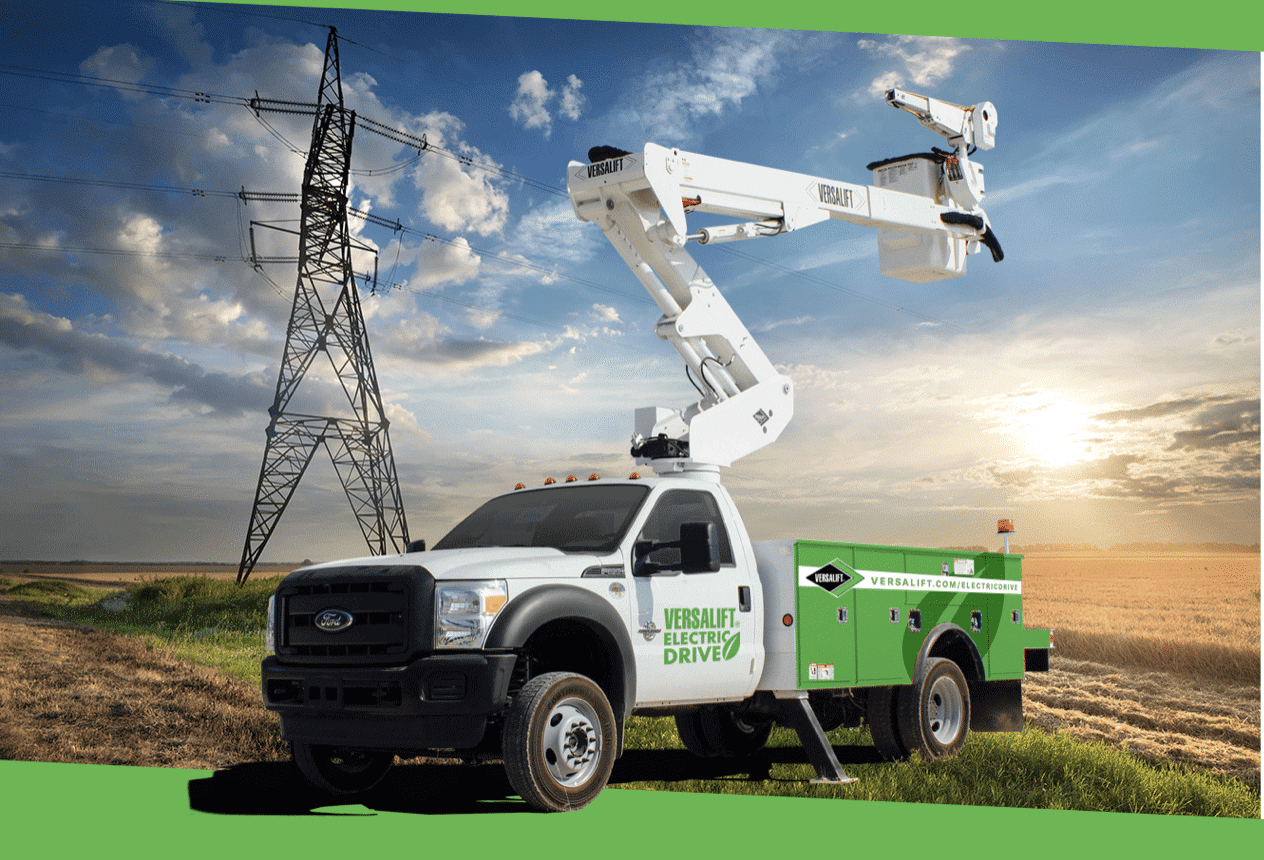

Electric Power Take Off (ePTO) – ePTOs are environmentally-friendly electric power take off systems that work with both our smaller and larger lifts. With Electric Drive™, which is available on all Versalift models, fleets can eliminate idle time and noise pollution, spend less money on fuel, decrease emissions, minimize impact on payload and reduce maintenance costs. Versalift distributors can calibrate our units to work all day, with fully functional hydraulic controls and boom speed, without burning fuel, and also source from other manufacturers. Electric Drive™ operates during aerial run time and enables full flow for hydraulic tool circuit operation, battery recharge of existing truck alternator, and full power-to-tool circuit operation.

Zero Emission Trucks (ZETs) – In Europe, Versalift International has developed fully-electric, vehicle-mounted aerial lifts. Additionally, Bluelift, a Time Manufacturing Company has pioneered fully electric and hybrid Compact Aerial lifts currently in use throughout the United States. As U.S. market-based Zero Emission Truck (ZET) and Zero Emission Van (ZEV) chassis become more readily available, Time Manufacturing Company brands are well-positioned to support their use across electric utility fleets.

Learn more about Time Manufacturing / Versalift’s Environmental, Social, and Governance programs at https://versalift.com/esg.

Explore related posts to learn more about Versalift’s products, customer stories, industry updates, and how we support essential infrastructure through innovation and service.

Advanced safety features like TruGuard™ and SlopeMax.

Our QA247 is the foundation of every product we assemble.

Heavyweight Performance – Best in class payloads and lighter chassis options.

We design our products with easy maintenance in mind.

Have questions about our bucket trucks or need help finding the right solution? Fill out the form below, and a member of our team will get back to you shortly.