Van Mounted Aerial Lifts

Van mounted aerial lifts for telecommunications, electric utility, sign & light industries

Versalift VANTEL van mounted aerial lifts give your crew the flexibility and capacity to handle daily tasks across industries like telecommunications, utilities, and sign & light. With a wide range of configurations, you get a lift that is tailored to your work, ensuring your crew has the right tool to get the job done safely and efficiently the first time.

Industries Served by the VANTEL Series

The Versalift VANTEL series of van-mounted telescopic bucket trucks supports crews across multiple industries, providing safe and efficient access for daily operations:

- Telecommunications – Expanding, upgrading, and maintaining communication networks.

- Electric Utility – Supporting crews with efficient service and repair access.

- Sign, Light & Traffic – Installing and maintaining streetlights, signage, and traffic signals.

- Distribution – Delivering reliable solutions for local power distribution systems.

Versalift Gives You Maneuverability, Capacity & Flexibility

Versalift van-mounted aerial lifts are a favorite in telecommunications and cable service because they combine safety, reliability, and efficiency in one compact package.

Built on the lightweight Ford Transit or Ram Promaster chassis, our VANTEL units stay under key weight thresholds even when loaded with tools, equipment, and two operators. This reduces regulatory pressure on fleets while keeping crews productive all day.

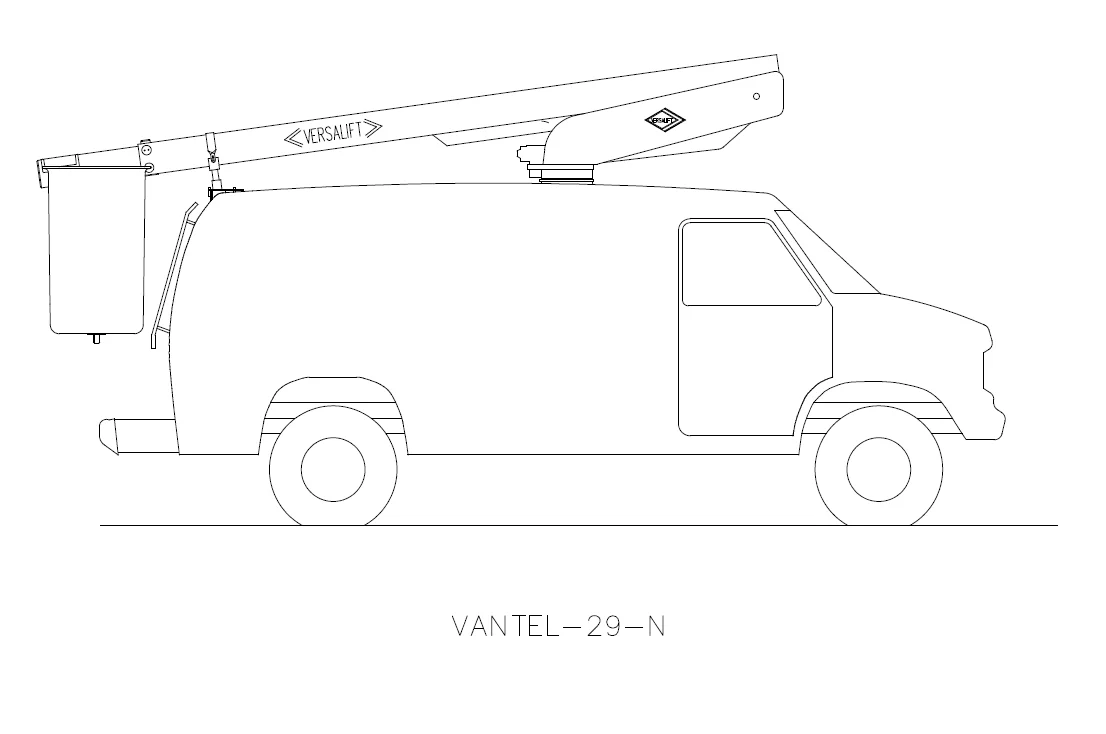

VANTEL-29 – Built for Tight Spaces

The VANTEL-29 is a versatile, maneuverable unit designed for suburban and urban work.

- Perfect for accessing overhead lines in densely populated areas

- Reaches narrow side streets and alleys with ease

- Doesn’t block traffic or require outriggers for stability

VANTEL Transit – Lightweight Advantage

Versalift was the first manufacturer to mount an aerial lift on the Ford Transit van — staying under the critical 9,000 lb GVWR threshold.

What this means for your crew:

- No DOT medical certification required → lower costs and reduced liability

- Lightweight upfit with shelves, racks, turret, boom, and storage

- Greater payload capacity and reduced maintenance expenses

Select Units (Non-Insulated): VANTEL-29-N, VANTEL-29-NE

Insulated VANTEL Cut-Away – Maximum Safety

The insulated VANTEL Cut-Away delivers unique safety advantages:

- Fiberglass inner boom instead of aluminum for insulation

- Electroguard® and TruGuard® safety systems included as standard

- Smooth, precise bucket control with full-pressure hydraulic upper controls

- Maximum operator protection at any height or position

Select Units (Insulated): VANTEL-29-I, VANTEL-29-IH, VANTEL-29-EI, VANTEL-29-EIH

Why Weight Matters for Fleets

Vehicle weight is a key differentiator for Versalift. Overweight service vehicles can create insurance risks and liability in the event of an accident.

By choosing our lightweight VANTEL units, you:

- Reduce liability exposure

- Lower insurance concerns

- Decrease wear on brakes, suspension, and transmission

- Extend vehicle service life and reduce maintenance costs

VANTEL Cut-Away – Heavy-Duty Option

For fleets that need more capacity, the VANTEL Cut-Away offers:

- 12,500 lb GVWR with dual rear wheels

- Multiple ceiling height options

- Greater payload and extra outer storage compartments

- Available in both insulated and non-insulated versions

Choosing Between Transit and Cut-Away

The right VANTEL model depends on how and where your crew works.

- Choose a VANTEL Transit for urban or suburban work, where tight spaces demand maneuverability. Transit units are lightweight, cost-efficient, and non-insulated, making them ideal for telecom, cable, and sign & light applications. They keep your fleet under regulatory weight limits while lowering operating costs.

- Choose a VANTEL Cut-Away if your work requires more payload, extra storage, or longer duty cycles. Built on a heavier chassis with dual rear wheels, Cut-Away units deliver added durability and capacity. Available in both insulated and non-insulated versions, they’re the right fit for utility, distribution, and safety-critical jobs.

Versatile Aerial Lifts Tailored for Your Industry

From utilities and telecommunications to tree care, signage, and wind energy—Versalift® builds aerial lifts that match the unique needs of your industry.

With proven reliability and the lowest true cost of ownership, our equipment keeps your teams working safely and efficiently.

Forestry & Tree Care

Specialized lifts for safe tree care applications

Explore our products

Sign, Light & Traffic

Efficient access for signs, lighting, and traffic systems

Explore our products

Tele-communications

Bucket trucks for maintaining telecommunications networks

Explore our products

Municipalities

Trusted fleet solutions for local infrastructure needs

Explore our products

Safety First

Advanced safety features like TruGuard™ and SlopeMax.

Quality Assurance

Our QA247 is the foundation of every product we assemble.

Lighter Build

Heavyweight Performance – Best in class payloads and lighter chassis options.

Easy to Service

We design our products with easy maintenance in mind.