Bucket truck safety comes from quality equipment, experienced professionals, and ongoing training. At Versalift, our top priority is the safety of the equipment operator, and we have consistently led the industry in the design and manufacture of bucket truck safety innovations including Electroguard, TruGuard™, and SlopeMax®.

-

Due to smarter and more reliable equipment designs, Versalift bucket trucks are the safest and most reliable bucket trucks in the industry.

-

Bucket truck operators understand that their most important responsibility is the safety of the job site.

-

Safety requires vigilance, training, expertise and reliable equipment.

-

Versalift is committed to a high standard of safety training, and the company offers on-line and in-person training for every piece of equipment delivered.

Below, readers will find a more detailed look at some of the key safety systems that come standard, or as options, on new Versalift bucket trucks.

Bucket Truck Safety System – Electroguard

Bucket truck safety includes ensuring that equipment is grounded at all times. ElectroGuard is one of several safety systems that comes on every insulated Versalift bucket truck. ElectroGuard ensures that the bucket truck remains grounded in every boom position across the working envelope, including fully deployed and fully stowed. This passive safety system is part of almost every insulated aerial lift manufactured by Versalift. Please click here to learn more about Electroguard, a Versalift safety innovation.

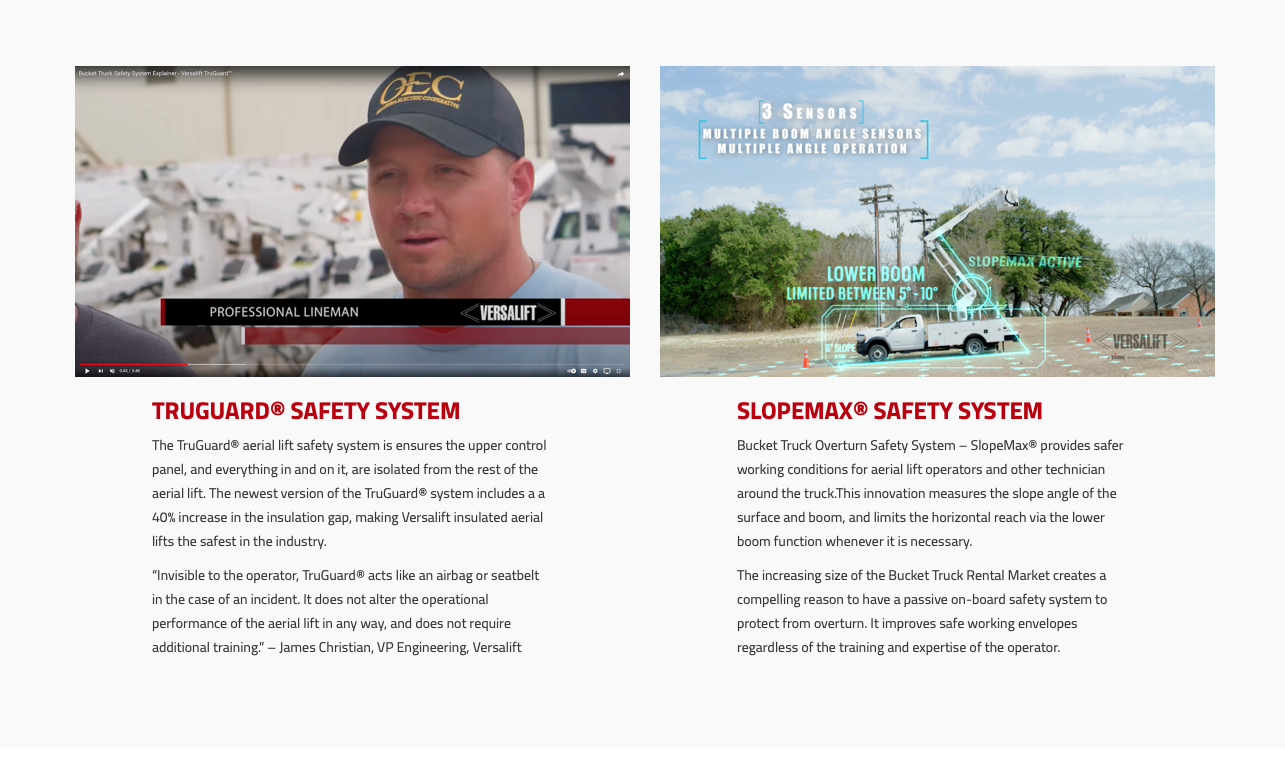

Bucket Truck Safety System – TruGuard™

Insulated bucket trucks are built and serviced by Versalift, and utilized by linemen, who perform electric utility infrastructure maintenance tasks. TruGuard™ is a safety system that isolates the entire upper control panel, and everything on it, from the rest of the vehicle. It does not alter the operation of the equipment in any way and requires no training. With no moving parts and requiring no service, TruGuard™ exceeds ANSI A92.2 standards for dielectric isolation. TruGuard™ now comes standard on every Versalift insulated bucket truck. Please click here to learn more about TruGuard™, a passive safety innovation that provides an additional layer of protection to the operator in the bucket.

Bucket Truck Safety System – SlopeMax®

Bucket trucks have, until recently, been required to operate on base slopes that do not exceed five degrees. A recent rules change from ANSI has put the onus on equipment manufacturers to make their equipment safe for operation, and to provide recommendations. SlopeMax is a simple, lightweight system of omnidirectional sensors that enable linemen to operate safely at base slopes of up to ten degrees. This safety innovation is crucial because it immediately impacts the market, saving lives by preventing unsafe operation. Please take a moment to read a more detailed technical explanation or to watch an explainer video about SlopeMax®, the most recent safety innovation brought to you by Versalift.

Bucket Truck Safety Training

Bucket truck safety ultimately relies upon the training and experience of the operator. It is a crucial step to provide thorough equipment training. Training on any bucket truck involves a daily checklist of pre-inspection points, safe set up and operation procedures, and emergency procedures. Ideally, employers should provide classroom learning and hands-on learning to technicians in order to ensure safe equipment operation. Learn more about bucket truck safety training for Versalift equipment operators. Versalift equipment training is available online, in a self-paced learning environment, and bucket truck training is also offered in a traditional, instructor-led classroom environment. Additionally, Versalift equipment service training is available, in order to ensure a higher level of maintenance quality, which makes equipment safer.