TruGuard™ – The world’s most advanced bucket truck safety system

Bucket trucks manufactured by VERSALIFT are engineered to be the safest equipment available on the market. Whenever a qualified electric utility technician works around electricity, there is a very real risk of injury or death. The risk of electrocution is something that no operator or business should tolerate, without doing everything they can to mitigate it. In the past, aerial lift manufacturers have offered solutions that include a plastic handle for limited dielectric protection at the upper controls. While these plastic handles may be somewhat useful, they are not a complete solution. Dirt and grime contamination, breakage and incomplete dielectric isolation are factors in why a plastic handle is simply not safe enough.

When James Christian, VERSALIFT’s Director of Engineering, started on the original design of TruGuard, he did so because he knew that the solutions provided by competitors in the marketplace, namely plastic handles and rubber boots, weren’t doing a good enough job. These “band-aid solutions” did not prevent contamination that was caused by environmental conditions during normal use. When grease, liquid, and dirt coats a plastic handle, its conductivity increases, which exposes linemen to greater risk of injury by electric power. In addition, expert technicians who are accustomed to using durable metal handles should not have to work with cracked or broken plastics that need replacement. Any distraction like this makes the already risky work environment more dangerous. Versalift is the only aerial lift manufacturer to offer this level of safety.

Bucket trucks are the most efficient way to put linemen in position to maintain and repair electric power lines. Innovations in bucket truck design have spurred massive improvements to the safety of electric utility technicians working at the platform. VERSALIFT is the industry leading innovator in bucket truck safety, and TruGuard™ is the world’s most advanced dielectric isolation system available on insulated bucket trucks.

TruGuard™ is now available as standard equipment on every Versalift insulated aerial lift.

At VERSALIFT, we believe that every operator and technician deserves the highest level of safety when faced with the everyday situations they encounter at work. This is exactly why our world-class engineers created TruGuard™ technology, the industry’s only complete upper control isolation system. TruGuard™ provides linemen with an additional layer of protection from phase-to-phase and phase-to-ground electrical contact when they are at the platform of an insulated bucket truck.

With TruGuard™, aerial lift operators experience unprecedented security and safety while working near electrical phases.

VERSALIFT has been a leader in bucket truck innovation for 50 years. TruGuard™ is a quantum step forward in lineman safety.

- Hydraulic Controls – TruGuard™ allows for full use of hydraulic controls and tool ports at the platform. This option is mechanic-friendly, operator-preferred and long lasting.

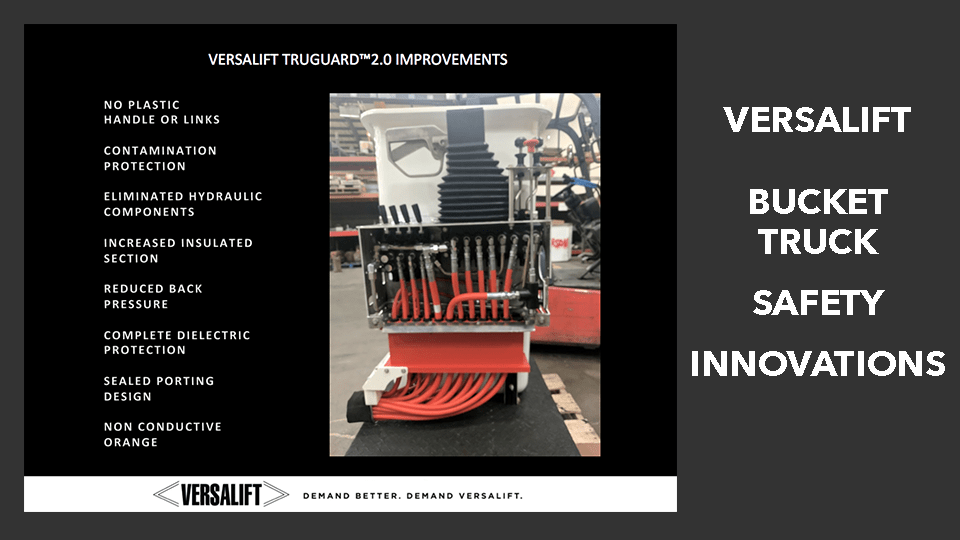

- Isolation Gap – TruGuard™ has a 44% increase in insulation gap over the previous system.

- Debris resistance – Easily surpasses the benchmark set by ANSI 92.2 requirements, while protecting surfaces from road grime and environmental contamination.

- Greatly simplified system – Redesigned for greater simplicity, TruGuard™ features 66 fewer hydraulic component parts than its original design.

TruGuard™ represents massive improvements in durability and reliability. We are so confident in the design, that it is now included as standard equipment on every insulated aerial lift we sell.

A stronger measure of safety and security for electric utility lift operators is possible.

If you are interested in learning more about TruGuard™ please contact one of our knowledgeable VERSALIFT distributors today.