Electric Utilities

Electric utility bucket trucks built for safety and efficiency

Versalift electric utility bucket trucks are engineered to support the critical work of utility providers with unmatched safety, reliability, and ease of operation. Designed for linemen and fleet managers alike, our insulated aerial lifts and digger derricks give crews the confidence to work productively in even the most demanding conditions.

For fleet managers and procurement officers, investing in a Versalift means more than just adding equipment to a fleet – it means securing a solution that reduces downtime, lowers maintenance costs, and delivers long-term value. With smarter designs, industry-leading insulation systems, and proven durability, every Versalift electric utility bucket truck helps keep crews safe at height while ensuring networks stay powered.

Bucket trucks and equipment for electric utilities

Every job in the electric utility industry demands equipment that is safe, reliable, and ready for daily use. Versalift offers a complete line of aerial lifts and digger derricks that help linemen work productively while protecting them at height.

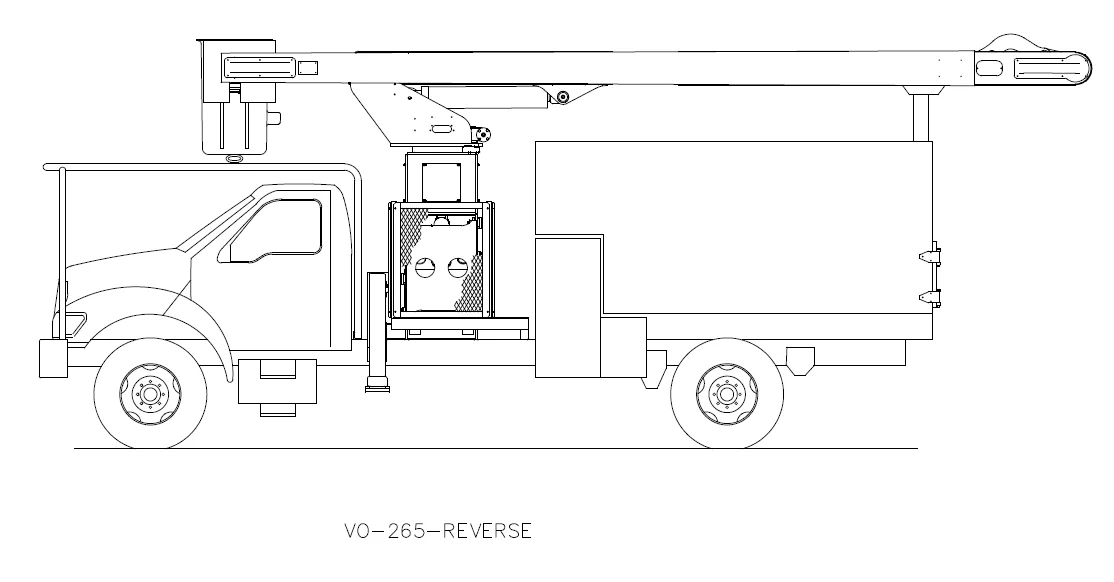

From insulated articulated telescopic bucket trucks to rugged digger derricks and high-reach transmission aerials, each model is built to support the demanding work of both power distribution and transmission. Crews can also rely on specialized equipment for extreme height applications, and our overcenter bucket trucks provide greater flexibility and precision when positioning around power lines.

Whether you’re maintaining local distribution networks or managing large-scale transmission projects, Versalift equipment is designed to deliver the performance, safety, and durability that electric utility professionals depend on every day.

Reliable bucket trucks with lower cost of ownership

Electric utility fleets face constant pressure to do more with fewer resources. That’s why Versalift designs every solution with safety, uptime, and total cost of ownership in mind. From distribution to transmission and pole setting, our bucket trucks and specialized equipment give crews the protection and performance they need, while helping fleet managers run more efficient and cost-effective operations.

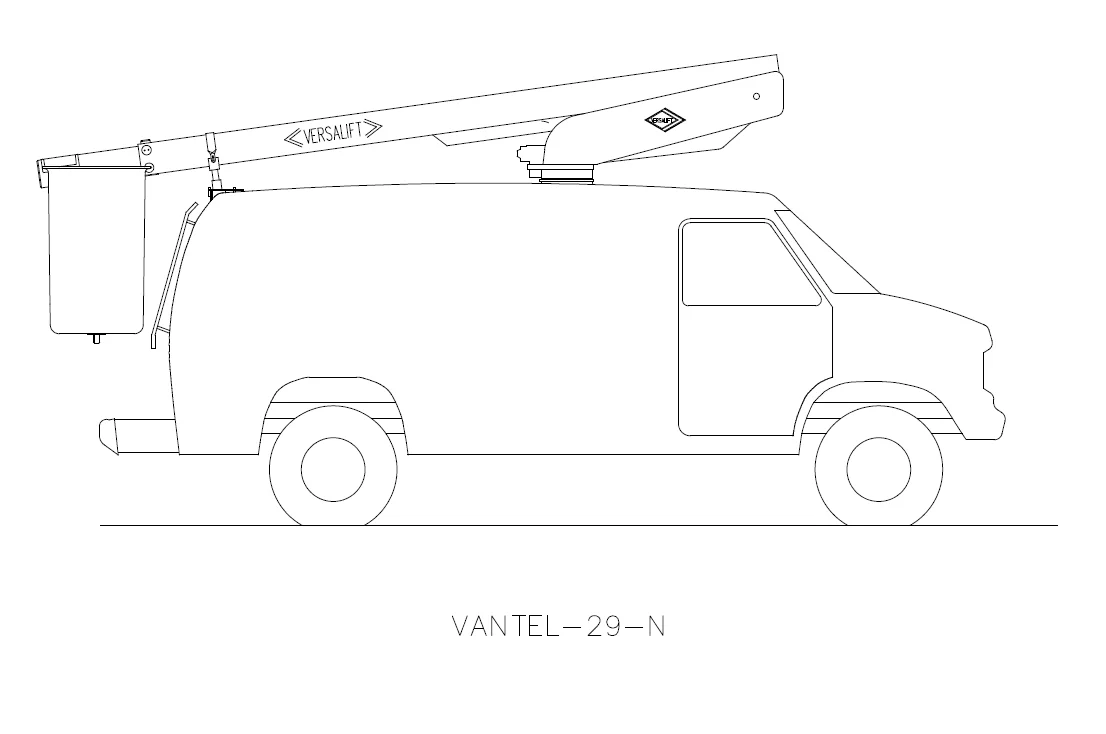

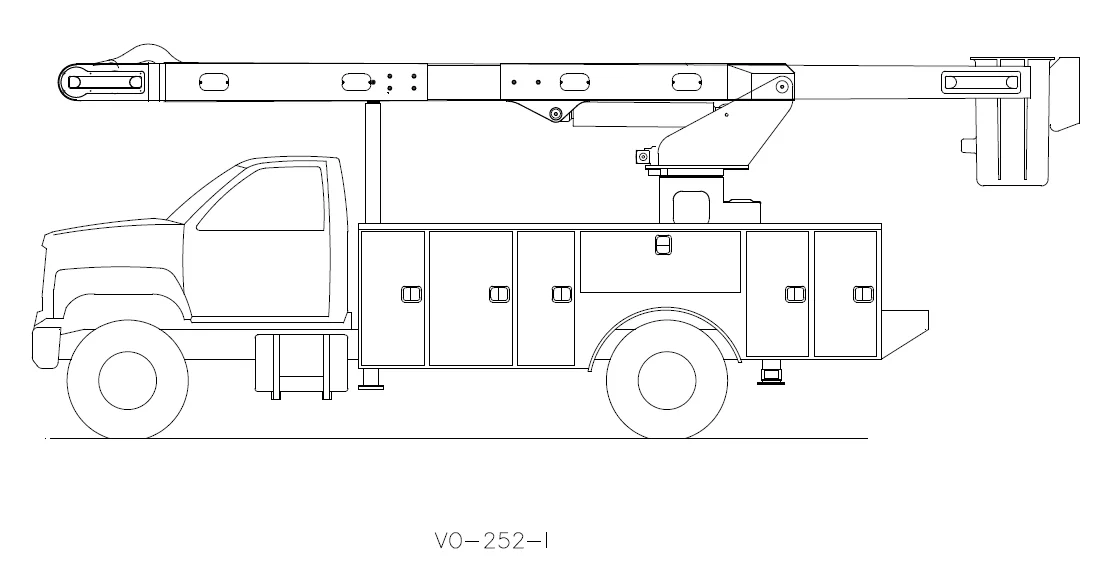

Distribution bucket trucks for electric utilities

Distribution work often takes place in challenging and hazardous conditions. Linemen need equipment that keeps them safe, while fleet managers demand reliability and low maintenance. Versalift electric utility bucket trucks are built with redundant safety systems, auto shut-off features, and advanced operator protection. By combining stability with long-term durability, our distribution bucket trucks deliver both safety and a lower total cost of ownership.

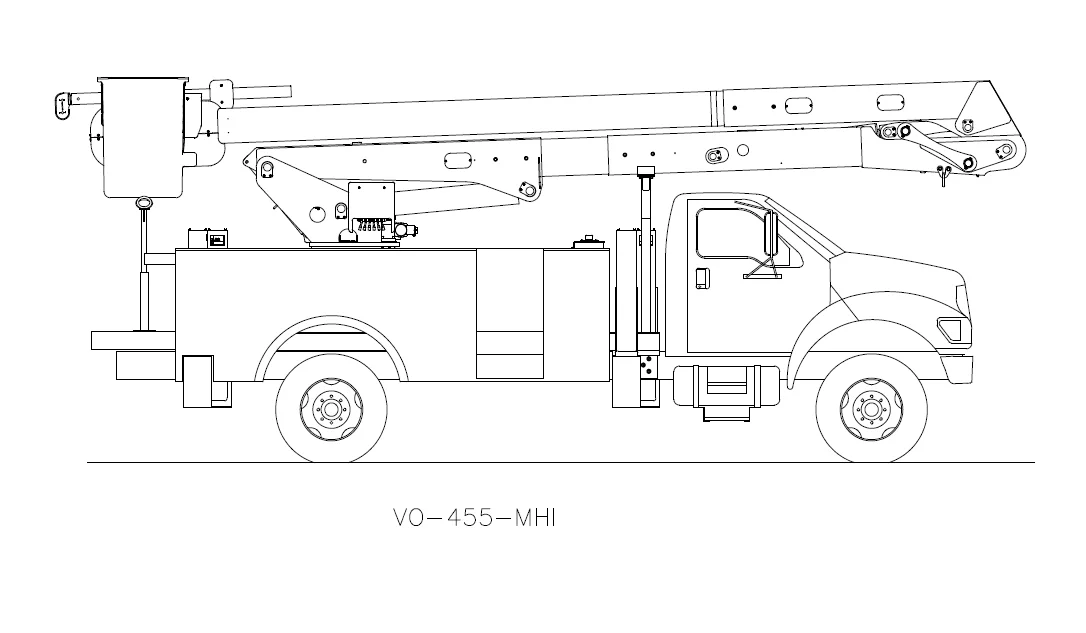

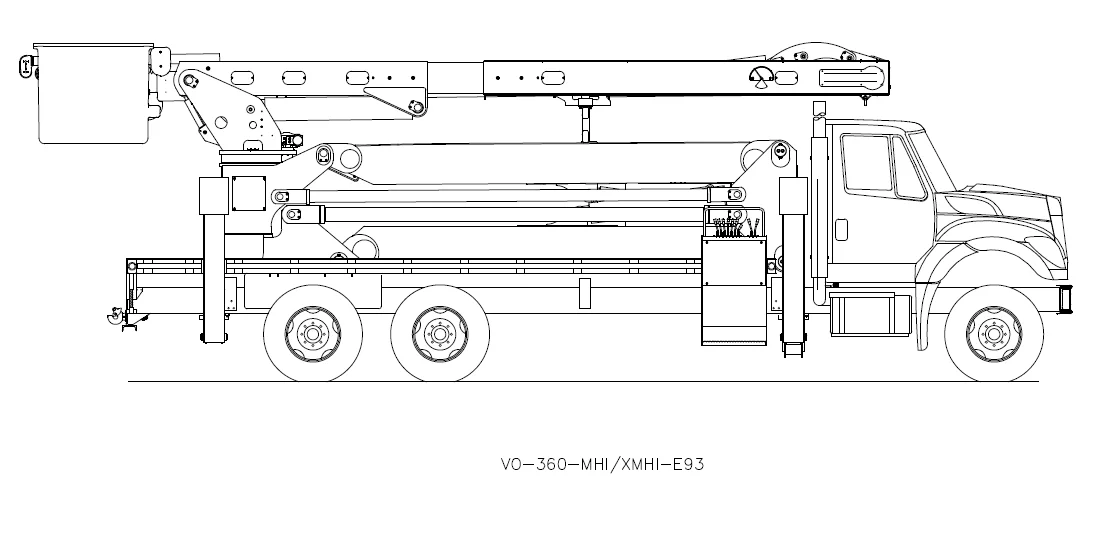

Transmission bucket trucks built for extreme heights

Transmission networks require equipment capable of safely lifting crews more than 200 feet into the air. Versalift transmission bucket trucks are engineered for these demanding jobs, with or without insulation systems, and all insulated models include TruGuard® – one of the industry’s most advanced safety systems – as standard. From high-reach aerial platforms to rugged digger derricks, our transmission solutions keep crews safe, reduce downtime, and lower lifetime costs.

High access platforms for transmission maintenance

Maintaining and servicing transmission infrastructure requires equipment with the reach and stability to handle large-scale projects. Versalift high access platforms, ranging from 104 to 220 feet, are the most comprehensive in North America. With advanced telematics, stability innovations, and efficient outrigger designs, these platforms give crews the working envelope they need while improving jobsite productivity and safety.

Digger derricks for power pole installation

Digger derricks are essential for setting poles and building reliable power networks. Versalift digger derricks are designed with the strength, range, and sheave height to handle heavy-duty utility construction. They integrate seamlessly with overhead telecommunications infrastructure, supporting multiple fleets on shared poles. With models featuring a horizontal reach of 50 feet and a sheave reach of 60 feet, Versalift digger derricks provide the power and flexibility electric utility fleets depend on.

Customer service that keeps your fleet working

Versalift supports electric utility fleets with a nationwide network of distribution, parts, and service centers. Our goal is simple: to keep your bucket trucks, digger derricks, and cable placers in service for as long as possible. With expert maintenance, testing, and support, we make sure your crews can stay focused on the work that matters – powering communities safely and efficiently.

Unlike many competitors, Versalift equipment requires no mandatory tear downs. This means less downtime, lower maintenance costs, and greater reliability over the lifetime of your fleet. It’s one of the many reasons why Versalift is recognized as the industry leader in safety, quality, and long-term value.

Every insulated aerial lift we produce is engineered to exceed ANSI and OSHA dielectric requirements, giving fleet managers and procurement officers peace of mind that their teams are working with the safest equipment on the market.

Versatile Aerial Lifts Tailored for Your Industry

From utilities and telecommunications to tree care, signage, and wind energy—Versalift® builds aerial lifts that match the unique needs of your industry.

With proven reliability and the lowest true cost of ownership, our equipment keeps your teams working safely and efficiently.

Forestry & Tree Care

Specialized lifts for safe tree care applications

Explore our products

Sign, Light & Traffic

Efficient access for signs, lighting, and traffic systems

Explore our products

Tele-communications

Bucket trucks for maintaining telecommunications networks

Explore our products

Municipalities

Trusted fleet solutions for local infrastructure needs

Explore our products

Unique Versalift Features Built Into Every Bucket Truck

Lower cost, higher lifetime value

Smarter engineering means lower operating costs. Versalift equipment is built to the highest quality standards, helping utilities reduce downtime, extend service life, and get the most value from every truck in their fleet.

Complete fleet support across North America

With more than 250 service locations across North America, a robust rental fleet, and competitive financing options, Versalift and its distributors provide a complete solution to keep utility fleets moving.

More uptime, less maintenance

Less time in the shop means more time on the job. Versalift aerial lifts require no mandatory tear-downs, and non-lube lift bearings are designed to last the life of the truck with minimal maintenance.

Built-in safety through every detail

Every component is built for safety and reliability. Torque striping on critical bolts allows operators to quickly verify equipment integrity during daily checks. Redundant pin-sets add another layer of protection to every lift.

Advanced safety systems you can trust

Versalift ElectroGuard and TruGuard® safety systems are industry-leading innovations that protect operators at any height or boom position, including when fully retracted. Together, they deliver the safest insulated telescopic aerial lifts available today.

Safety First

Advanced safety features like TruGuard™ and SlopeMax.

Quality Assurance

Our QA247 is the foundation of every product we assemble.

Lighter Build

Heavyweight Performance – Best in class payloads and lighter chassis options.

Easy to Service

We design our products with easy maintenance in mind.