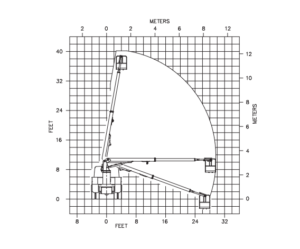

Bucket Truck for Sale – VERSALIFT VTP-40-NE a non-insulated, 35 ft. (10.7 m) telescopic articulating aerial platform lift, 40 ft. (12.2 m) working height including the following standard and optional features:

- Standard platform capacity of 350 lbs. (158 kg), plus 150 lbs. (68 kg) cable down force.

- Boom tip side load capacity is 600 lbs. (270 kg) when fairlead retracted and 450 lbs. ((200 kg) when extended.

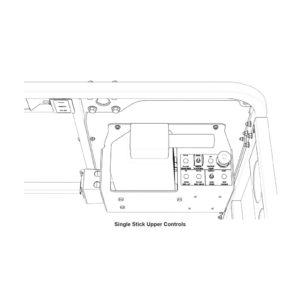

- Full pressure UNITROL single stick control with integral safety trigger and emergency stop control

- Engine start/stop system with controls at platform and lower controls.

- 370° non-continuous rotation with a hydraulic stop.

- Closed center hydraulic system operates at 12 GPM (38 LPM) at 2250 psi (175 kg/cmۜ)

- Integral hydraulic oil reservoir with 30 gallon (115 liter) capacity.

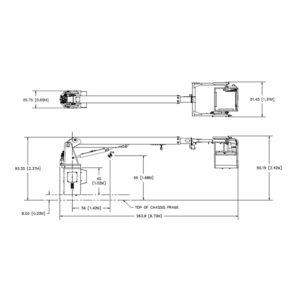

- Outer boom consists of a 10 in. x 10 in. (254 mm x 254 mm) steel section

- 8 in. x 8 in. (203 mm x 203 mm) rectangular steel inner boom is housed within the outer boom.

- 32 in. x 32 in. x 42 in. (0.81 m x 0.81 m x 1.09 m) steel platform with door and safety chain.

- Intercom with cab and platform speakers and volume control in cab

- 2000 lbs. (900 kg) rated lower boom lifting eye

- 12 volt DC backup pump providing power to all boom functions.

- 6000 lbs. (2700 kg) reel loader for reels up to 64 in. (1.7 m) wide and 84 in. (2.1 m) diameter

- Hydraulic powered cable retriever drive includes clutch to allow the reel to free wheel and hydraulic caliper disc brake to tension cable. Provides 36,000 in-lbs. (4070 N-m) drive and torque and a maximum drive speed off approx. 12 rpm. The reel drive control is included with the lower control pendant and the proportional reel brake is located in the cab.

- 2000 lbs. (900 kg) capacity strand carrier designed to carry strand reels up to 28 in. (0.71 m) wide and 32 in. (0.81 m) diameter, includes a hydraulic caliper disc brake to tension the strand providing 9600 in-lbs. torque. The proportional reel brake control is located in the cab.

- Swivel bull wheel system, mounted on boom rest

- Deck mounted four-way roller fairlead (bolted behind pedestal)

- Complete sub-frame and mounting hardware for chassis/cab installation.

- Complete boom rest assembly with polyethylene cradle for outer boom.

- GFCI receptacle for 120 volt power at platform

- Remote wired lower control box with the following functions: boom up/down, extend/retract, rotate, leveling, winch, reel lift, reel drive and capstan.

- Tow line winch (worm gear type) mounted at lower boom rest structure, includes control at platform and pedestal with 70 ft. of rope installed. Bare drum capacity of 1500 lb.

- Worm gear capstan assembly to the curbside reel lift arm

- PTO and pump for mobile operations with over speed limit (2250 psi, 12 GPM at idle, closed center)

- Aluminum tool tray 6.25 in. x 12 in x 23 in (160 x 305 x 580 mm) attaches to top rail of platform.

- Aluminum small parts tray 5 in. x 5 in. x 19 in. (130 x 130 x 480 mm) attaches to platform or tool tray.

- Full body harness and lanyard.

- Painted standard white urethane.

- Two operator’s manuals and two service manuals.

- ANSI A92.2 data plate

Cab and chassis to the following specifications:

- Ford F-750 4×2 cab and chassis.

- 25,999 lb. GVWR.

- 84” cab to axle.

- 7L Power Stroke V8 (270 HP) Turbo diesel engine

- Ford TorqShift HD 6-Speed automatic transmission

- Single channel – straight “C” 14.18 SM, 120,000 PSI frame

- 50 limited slip axle.

- Hydraulic brake system – Bosch HydroMax

- 5×8.25 powder coated steel disc wheels with 11R22.5G tires.

- 30/70 Air ride driver (Integral air pump) and fixed 2-passenger bench – vinyl

- AM/FM radio.

- Painted Oxford White.

Steel Service Body 135 in. long x 47 in. high x 94 in. wide to include the following:

- 47 in. compartment height, 20 in. compartment depth, 54 in. floor width.

- Stainless steel automotive rotary type door latches, with chain stops on all doors

- Rubber rolled crown type fenders

- Wheel chock storage with pendulum retainer

- 6 in. removable composite rails x full perimeter of tailshelf (incl. rear) for material containment

Curbside compartments as follows:-

- 1st Vertical (32 in.): Nine (9) fixed material hooks 3-3-3, one fixed shelf

- Access Steps: 24 in. wide, hinged gripstrut access steps with battery storage with one (1) gas assist door opener, two (2) chrome handles and one (1) cable step

- Horizontal (57 in.): Open

- Curbside Tailshelf Box: 28 in. x 24 in. x 20 in. box with vertical hinged access door

Streetside compartments as follows:

- 1st Vertical (25 in.): Six (6) fixed material hooks 3-3-0

- 2nd Vertical (25 in.): Six (6) fixed material hooks 0-3-3, NO wall between 1st and 2nd verticals

- Horizontal (57 in.): Open

- Streetside Tailshelf Box: 28 in. x 24 in. x 20 in. box with vertical hinged access door

Installation to include the following:

- Install VERSALIFT VTP-40-NE, mounting hardware, PTO and pump.

- Install rear torsion bar.

- Install Dakota service body and accessories

- Paint body and accessories white and non-skid body floor area.

- Install amber strobe lights one each side of turret.

- Install front strobe lights in grille and rear strobe lights on rear body panel

- Install Dimensions Pure Sine inverter with battery to be tied into 120V outlets at platform.

- Install brake controller, T-60 medium duty pintle hook, D rings, 4-way and 6-way trailer connector

- Install rear mud flaps and pipe cone holder with base (located to rear of tower on body floor).

- Install manual holder in cab and five (5) gallon water cask with storage bracket on top of body compartment.

- Install fire extinguisher with storage bracket (mount inside streetside front compartment)

- Mount convex mirror (top of streetside mirror) to view basket during mobile operation.

- Furnish ten unit medical kit including supplies, pair of rubber wheel chocks and DOT triangle type road reflector kit.

- Test ride completed unit for 1 hour.

- Test and certify per ANSI A92.2.