Digger Derricks

Digger Derricks for Electric Utility and Telecommunications Construction

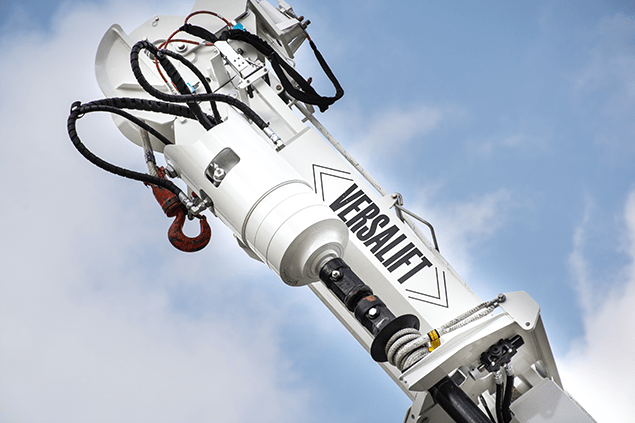

Versalift Digger Derricks are engineered for durability and stability, with redundant safety features and a set of hydraulic systems to operate the booms, digger and winch independently of the others.

What makes Versalift digger derricks so valuable?

Versalift digger derricks deliver a lower true cost of ownership through smarter, more reliable design. With a range of digger derricks, purposed for both utility distribution and telecommunications, Versalift distributors deliver a complete fleet solution, with scheduled maintenance, annual inspections, on-site repairs, parts, training and the best warranty rate in the industry.

Digger Derrick - Highlights

Explore Options

DIGGER DERRICKS WITH A LOWER TRUE COST OF OWNERSHIP

Digger Derricks Are Heavy Hydraulic Equipment

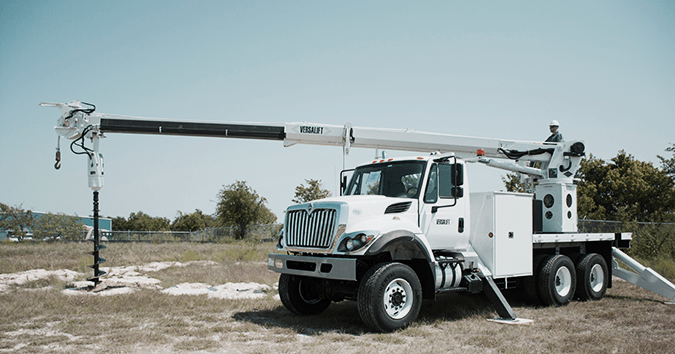

A Versalift digger derrick is a good example of highly specialized hydraulic equipment that is used in the utility and telecommunications industries. Digger derricks are used to dig holes, set poles and handle an assortment of materials. They are especially valuable in construction of new networks, and in replacing infrastructure damaged by inclement weather or disaster.

Digger Derrick – Operational Factors

Digger derricks should be operated from firm ground, and they perform best when digging in earth that isn’t frozen. While seasonal changes play a role in how efficiently crews can dig holes and set poles, ground type is an equally important factor. Depending upon the environment and type of work, digging radius and sheave height determine how to position the equipment. Equipment reliability is always at the heart of operational success, and Versalift equipment is easier to maintain.

- Sheave Height – the height of a fully extended boom when it is at maximum elevation.

- Digging Radius – the maximum circular reach of the boom

- Jib/Winch Capacity – the amount of weight that a jib and winch can lift

Digger Derricks With A Lower True Cost Of Ownership

Versalift Digger Derricks offer fleets a lower true cost of ownership, with best in class payload due to smarter, lightweight design. Customers experience ease of maintenance, because the units feature non-lube bearings, and a single grease fitting for the rotation bearing. Two sets of controls are available on Versalift digger derricks: full pressure Hydraulic controls with open center system, and radio remote controls with closed center hydraulic system. Contact your Versalift distributor for options and configurations.

Parts, service or warranty questions can be answered the Versalift Customer Support Center directly at (866) 543-8887 [866-LIFT-U-UP].

Digger Derrick Warranty Features at Versalift

All digger derricks that are manufactured by Versalift come with a standard manufacturer’s warranty, with a standard, one-year warranty for parts, and a lifetime warranty on structural components. Our customers have the option of extending the standard manufacturer’s warranty.

More Reliable Design, Lowest Warranty Rate, Fewest Recalls

Versalift digger derricks create a lower true cost of ownership due to smarter, more reliable design.

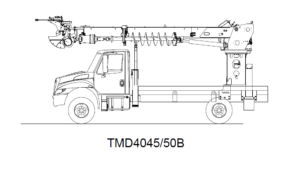

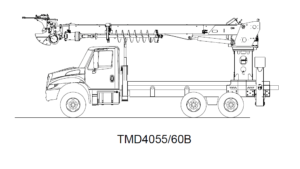

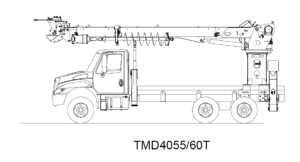

TMD-4060-T Heavy Duty Digger Derrick – Several configurations available

- Maximum Capacity – 29,200 lbs

- Capacity at 10’ Radius – 16,600 lbs

- Horizontal Reach – 50.2’

- Sheave Height – 60.2’

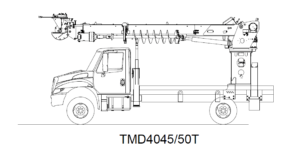

TMD 2047-T Medium Duty Digger Derrick – Most horizontal reach and sheave height in its product class

- Maximum Capacity – 25000 lbs

- Capacity at 10’ Radius – 11200 lbs

- Horizontal Reach – 37.8’

- Sheave Height – 48.1’

TMD-4050-T – Heavy Duty Digger Derrick

- Maximum Capacity – 29200 lbs

- Capacity at 10’ Radius – 16600 lbs

- Horizontal Reach – 50.2’

- Sheave Height – 60.2’

Digger Derrick Operational Training

Digger derrick training support for equipment operators and maintenance technicians is available through Versalift Training Programs. Versalift online training programs provide the most advanced and interactive operator and maintenance training platform in the industry. Our training programs are programmatically aligned with ANSI A92.2 recommendations and OSHA standards. While there is no substitute for familiarity with the actual equipment and practical, hands-on training, our courses build familiarity with with how to safely operate and maintain Versalift equipment.

Industries Served

Digger Derricks are frequently utilized by the electric power distribution, electric power transmission and telecommunications industries to build and repair networks of overhead infrastructure.

Individual Digger Derricks - Capacity Charts

At Versalift, we determine the load capacity of each Digger Derrick by setting the boom angle at 80 degrees, and retracting the intermediate and upper booms, so that the outside edge of the sheave is 10 feet off the centerline of the rotation bearing of the boom. By testing for load capacity on each unit we build, we are able to assure the highest quality, and deliver an individual capacity chart for each product we build for our customers.

WORLD’S FIRST ARTICULATED TELESCOPIC AERIAL DEVICE - 1980

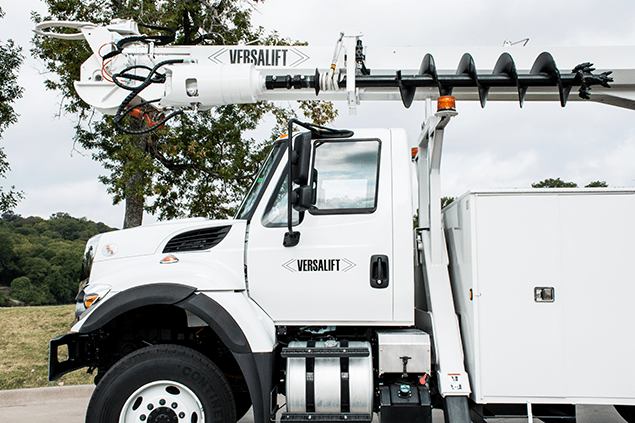

A lot has changed since we built our first aerial lift in 1965. But one thing that has not is our approach. We build every Versalift to last, it is not unusual to see a 30 year old Versalift Bucket Truck being used daily!

UNIQUE VERSALIFT FEATURES

A culture of innovation and quality at Versalift powers our passion to be the best.

- Lower True Cost of Ownership - Engineered to the highest standards of quality, our bucket trucks, high reach units and digger derricks feature smarter, more reliable design for a lower true cost of ownership.

- Full Service Provider - With more than 250 service locations in North America, rental fleet coverage and competitive equipment financing, Versalift distributors deliver a complete fleet solution.

- Ease of Maintenance - Versalift equipment spends more time in service, and less time in the shop. Non-Lube lift bearings require less maintenance, and are designed to last the practical life of the truck. Versalift aerial lifts have no mandatory tear-downs.

- World’s Most Advanced Safety Systems - Versalift Electroguard and TruGuard® safety systems combine to offer the safest telescopic insulated aerial units on the market, at any height and position, including fully retracted

- Attention to Detail - Torque striping is an extra step taken to ensure the quality of your equipment. All critical bolts are torque seal marked, which allows lift operators to efficiently conduct daily visual inspections. Additionally, every critical pin on the bucket truck and lift assembly has a redundant pin-set, which is then torque striped.

About Versalift

As the industry quality leader in bucket trucks, Versalift also manufacturers aerial devices, digger derricks and other specialty equipment for power generation, transmission and distribution, investor-owned utility, telecommunication, light & sign, and tree care industries. Working with co-ops, municipalities, government agencies and corporations through its global network of facilities and family of distributors, the company manufactures, sells and services bucket trucks in North America, South America, and Europe and employs nearly 700 associates worldwide. For further information about telescopic articulated bucket trucks please contact us at sales@versalift.com.